Product introduction

The metal shavings briquetting machine is primarily used to cold-press metal shavings, powders, or granular materials such as waste copper, waste aluminum, cast iron chips, steel chips, iron ore powder, silicon powder, and slag powder into cylindrical briquettes weighing 2.5-10kg. Without adding any additives, this equipment is suitable for enterprises with large metal chip volumes, large foundries, wind power component casting enterprises, and copper-aluminum product manufacturers.

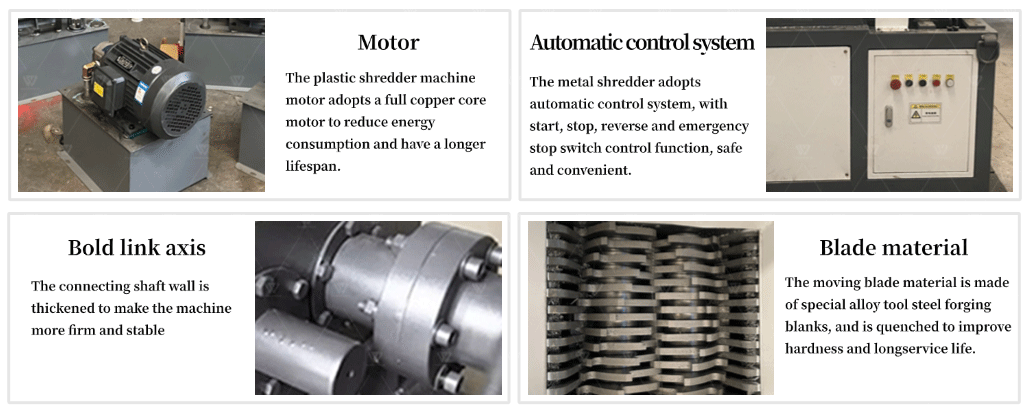

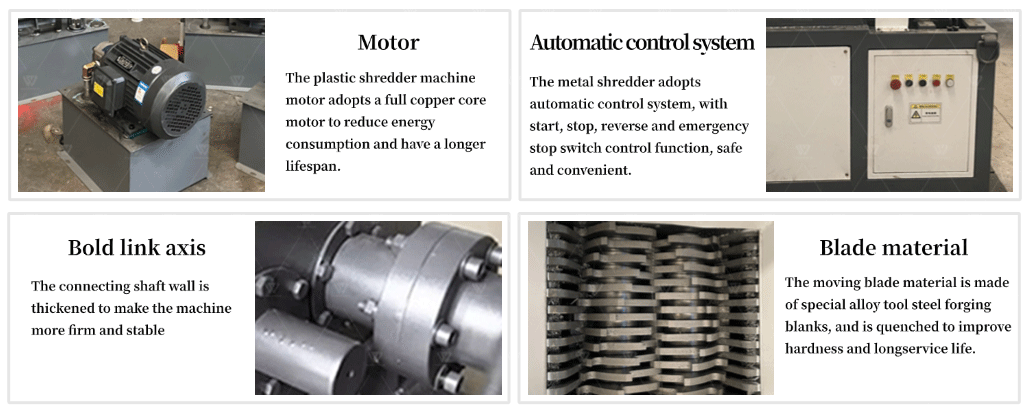

The main body of the shredder machine is produced in the whole one, using high-quality steel plate welding to eliminate the stress and to ensure the stability of the equipment in the long heavy load. The blade holder and blade on the rotor can be disassembled for easy cleaning, maintenance and maintenance; The plastic shredder machine has the advantages of even unloading, high tearing efficiency, large output, reliable performance, etc. It can be widely used in the garbage recycling industry.

Metal Shavings Shredder is widely used in industrial scrap metal recycling, plastic recycling, tire recycling, electronics manufacturing, pallet manufacturing, wood processing, paper industry, domestic waste recycling and other fields. It is suitable for crushing solid materials; For example electronic waste, metal, wood, plastic, waste tires, chemical drums, pallets and so on.

Metal Shavings Shredder has the advantages of smooth operation, low noise, high torque and so on. The material is pushed into the shredding chamber by the conveyor belt, and the two sets of knife shafts of twin shaft shredder rotate at different speeds, so as to shear and shred the material at the same time, which improves the shredding efficiency.

Metal Shavings Shredder has the advantages of smooth operation, low noise, high torque and so on. The material is pushed into the shredding chamber by the conveyor belt, and the two sets of knife shafts of twin shaft shredder rotate at different speeds, so as to shear and shred the material at the same time, which improves the shredding efficiency.

The knives of the waste paper shredder are made of special alloy steel by special processing, with better wear resistance, higher strength, repairable and other characteristics. The housing is flattened and disassembled, can quickly remove the movable knife, fixed knife, bearing, and other components, easy to maintain and replace tools.

| Model |

Spindle power (kw) |

Spindle speed (r/min) |

Output (t/h) |

Conveyor power (kw) |

Number of cutter discs (pieces) |

Cutter disc diameter (m/m) |

Crushing size (am) |

Binyard size (m) |

Length, width and height (m) |

Weight (t) |

| WSD-2600 |

4-160*2 |

16-18 |

25-60 |

4-3kw |

40 |

Ø720 |

3-10 |

2.5*14 |

8 2*4*4 3 |

36 |

| WSD-1900 |

4-90*2 |

14-16 |

10-25 |

4-3kw |

40 |

Ø560 |

3-10 |

23*2 |

8*2.5*2.4 |

15 |

| WSD-1500 |

4-45*2 |

14-16 |

8-18 |

4-3kw |

30 |

Ø530 |

3-10 |

2*2 |

4*1.7*2.4 |

12 |

| WSD-1200 |

4-37*2 |

18-20 |

6-15 |

None |

28 |

Ø372 |

3-10 |

14*1 |

3.2*2*1.9 |

6 |

| WSD-1000 |

4-30*2 |

18-20 |

5-10 |

None |

30 |

Ø360 |

3-10 |

1.2*1 |

3*2*19 |

5 |

| WSD-600 |

4-15*2 |

18-20 |

2-5 |

None |

26 |

Ø260 |

3-10 |

0.82*0.9 |

2.6*2*1.9 |

2.5 |