Product introduction

The double-shaft shredder can meet the waste recycling requirements of various industries and is suitable for shredding thick and difficult-to-shred materials.With the development of modern society, people pay more and more attention to the secondary recycling of waste, which represents the progress of the times. The dismantling of old car shells, the reduction of domestic waste, and the crushing and recycling of ton bags all require large-scale mechanized processing.

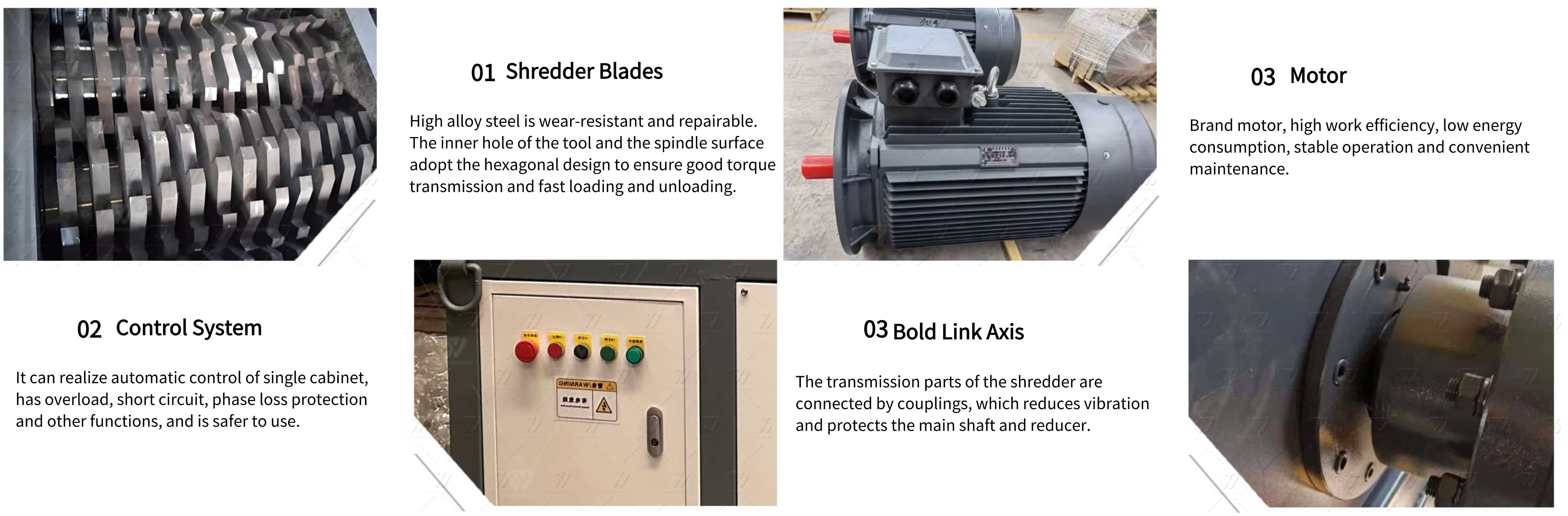

The double-shaft shredder is a solid waste volume reduction mechanical environmental protection shredder equipment, mainly composed of a blade spindle, a fixed blade, a bearing box, a box bracket, a feeding system, a hydraulic pushing system, a power system, and an electrical control system. The double-shaft shredder is generally used to process unprocessed raw materials or scraps to make them smaller in size. According to actual conditions, it is improved, developed, and launched a series of double-shaft shredders with mature technology and design, providing reliable quality equipment for the crushing and volume reduction treatment in the early stage of waste recycling.

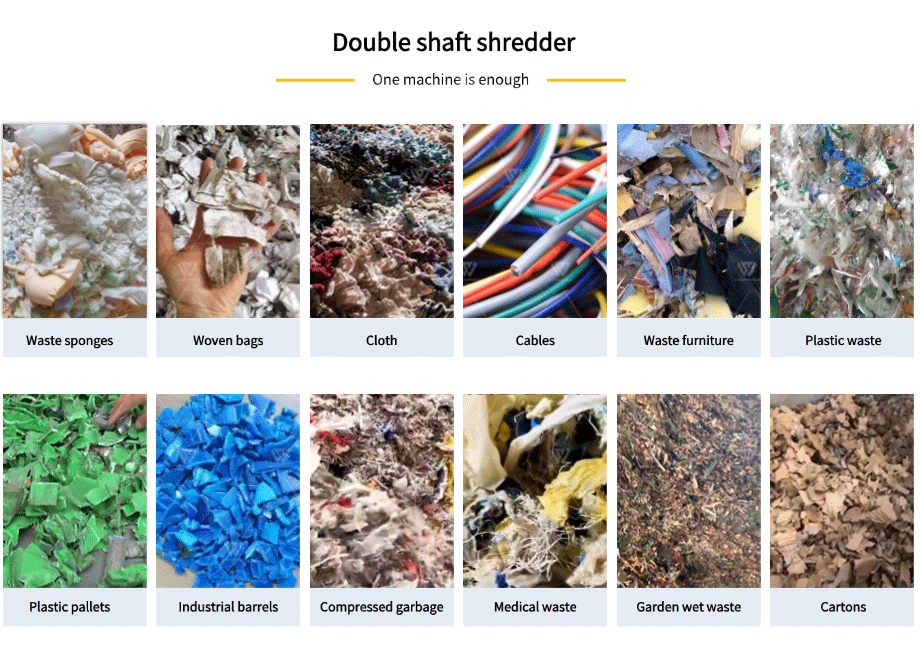

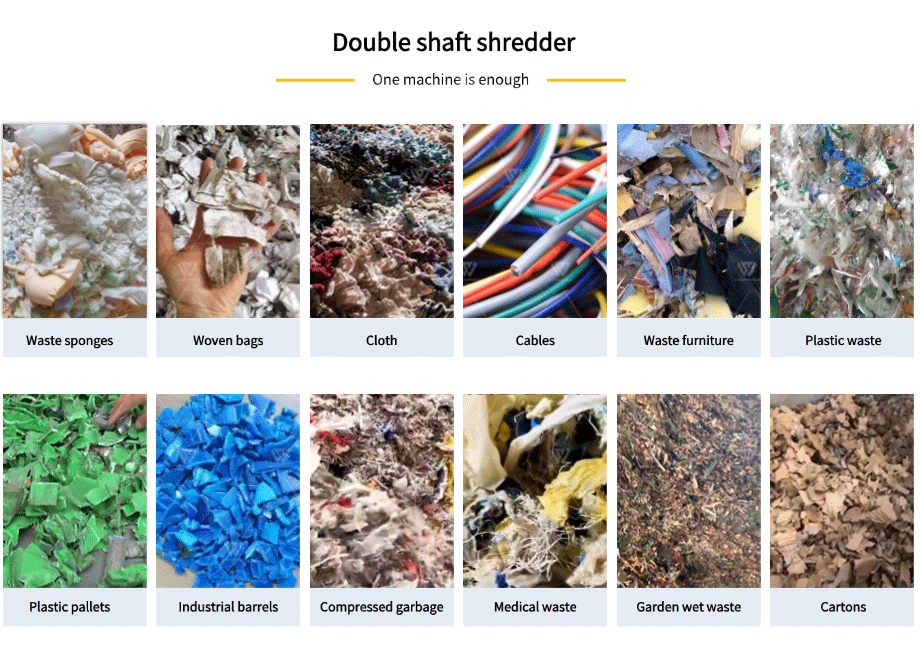

The double-shaft shredder can meet the waste recycling requirements of various industries and is suitable for shredding thick and difficult-to-shred materials, such as: waste automobile shells, domestic garbage, plastics, metals, wood, waste rubber, packaging barrels, pallets, ton bags, waste plastics and other large materials.The double-shaft shredder can recycle a wide variety of materials. The shredded materials can be directly recycled or further refined according to needs. It is suitable for industrial waste recycling, medical recycling, electronic manufacturing, pallet manufacturing, wood processing, domestic waste recycling, plastic recycling, tire recycling, papermaking and other industries.

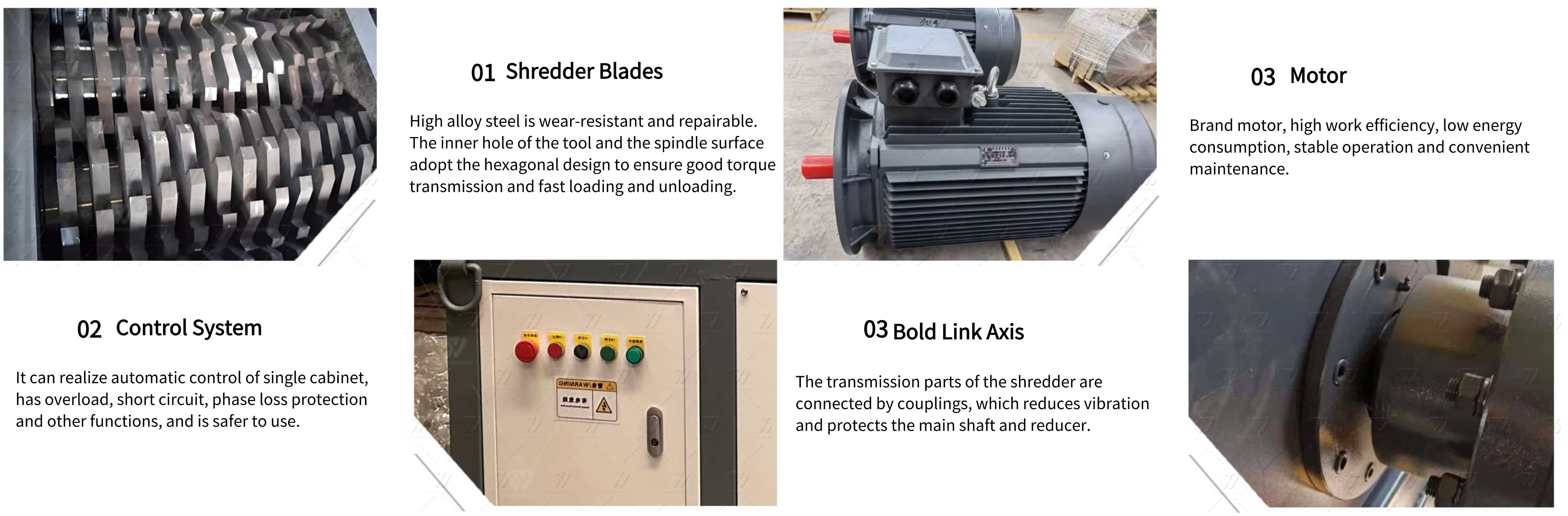

The main body of the double-shaft shredder is made of steel plates processed and welded as a whole to ensure the stability of the equipment under long-term load. The moving knife material is made of special alloy tool steel forging blanks, precision machining, multiple heat treatments and low-temperature freezing heat treatment technology to ensure cutting performance and service life.

| Model |

Spindle power (kw) |

Spindle speed (r/min) |

Output (t/h) |

Conveyor power (kw) |

Number of cutter discs (pieces) |

Cutter disc diameter (mm) |

Crushing particle size (cm) |

Binyard size (m) |

Length, width and height (m) |

Weight (t) |

| WSD-2600 |

4-160*2 |

16-18 |

25-60 |

4-3kw |

40 |

∅720 |

3-10 |

2.5*1.4 |

8.2*4*4.3 |

36 |

| WSD-1900 |

4-90*2 |

14-16 |

10-25 |

4-3kw |

40 |

∅560 |

3-10 |

2.3*2 |

8*2.5*2.4 |

15 |

| WSD-1500 |

4-45*2 |

14-16 |

8-18 |

4-3kw |

30 |

∅530 |

3-10 |

2*2 |

4*1.7*2.4 |

12 |

| WSD-1200 |

4-37*2 |

18-20 |

6-15 |

None |

28 |

∅372 |

3-10 |

1.4*1 |

3.2*2*1.9 |

6 |

| WSD-1000 |

4-30*2 |

18-20 |

5-10 |

None |

30 |

∅360 |

3-10 |

1.2*1 |

3*2*1.9 |

5 |

| WSD-600 |

4-15*2 |

18-20 |

2-5 |

None |

26 |

∅260 |

3-10 |

0.82*0.9 |

2.6*2*1.9 |

2.5 |