Product introduction

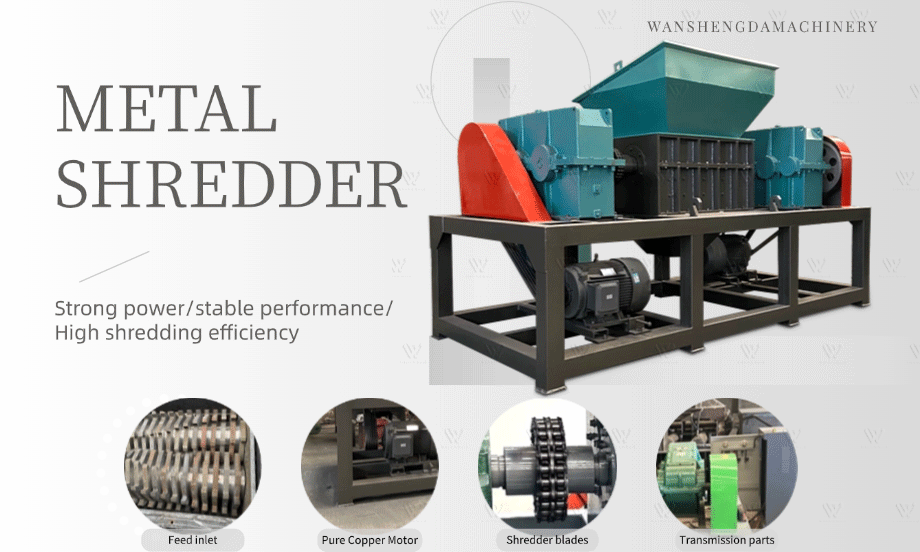

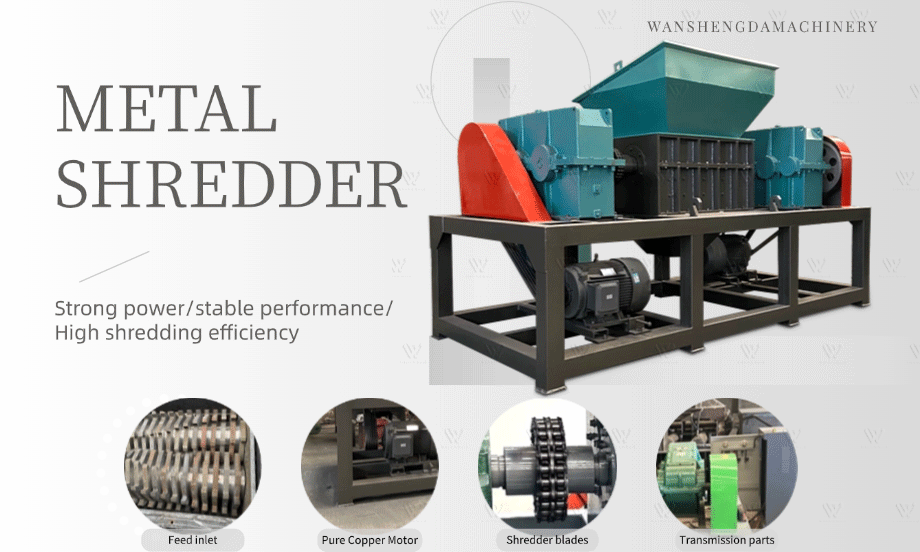

Metal shredders can quickly shred large pieces of scrap metal materials, and the shredded products can be equipped with production lines according to user needs or directly recycled for secondary use.Metal shredders are mainly used in: scrap steel recycling companies, metal smelting, construction industry, metal recycling industry, car recycling companies, etc.

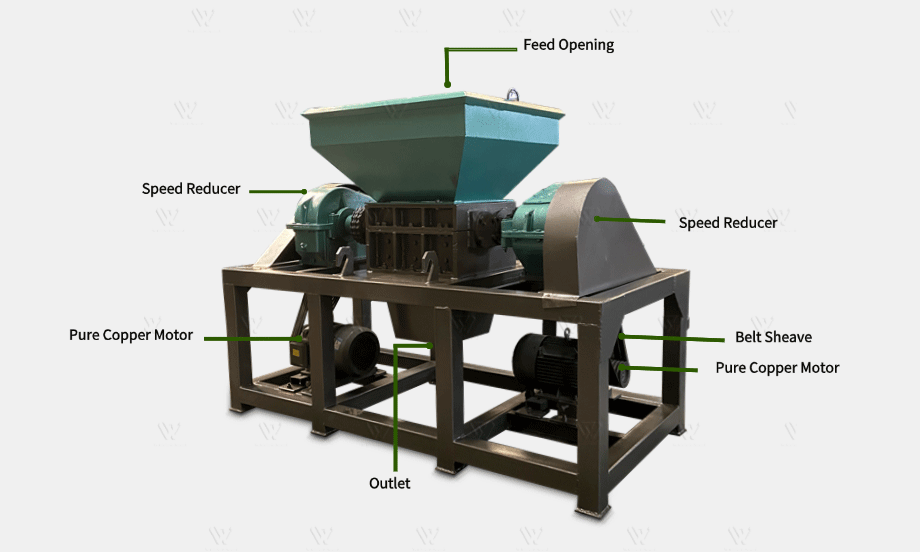

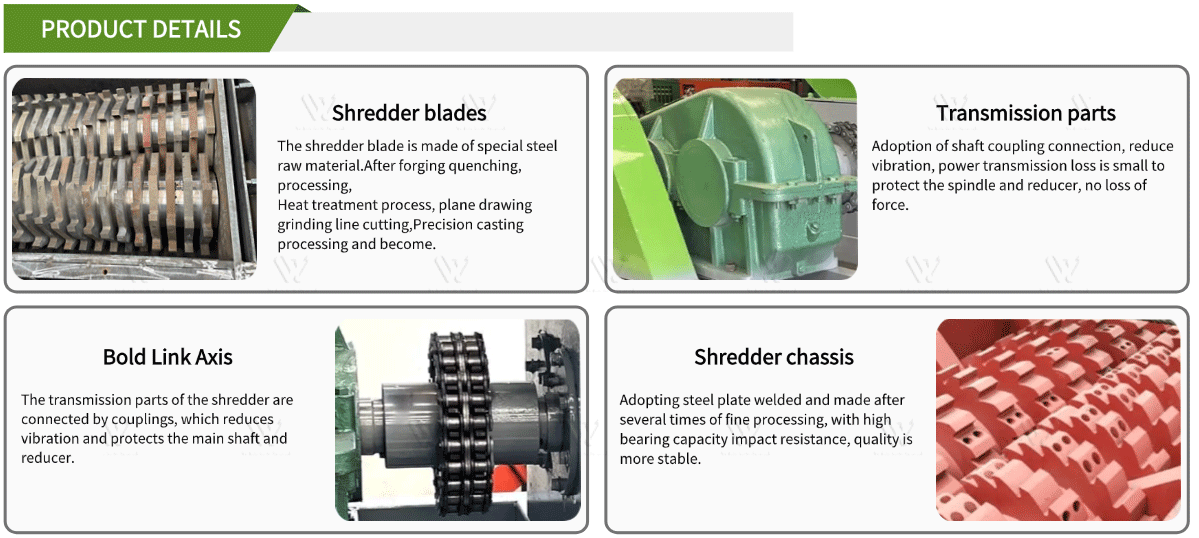

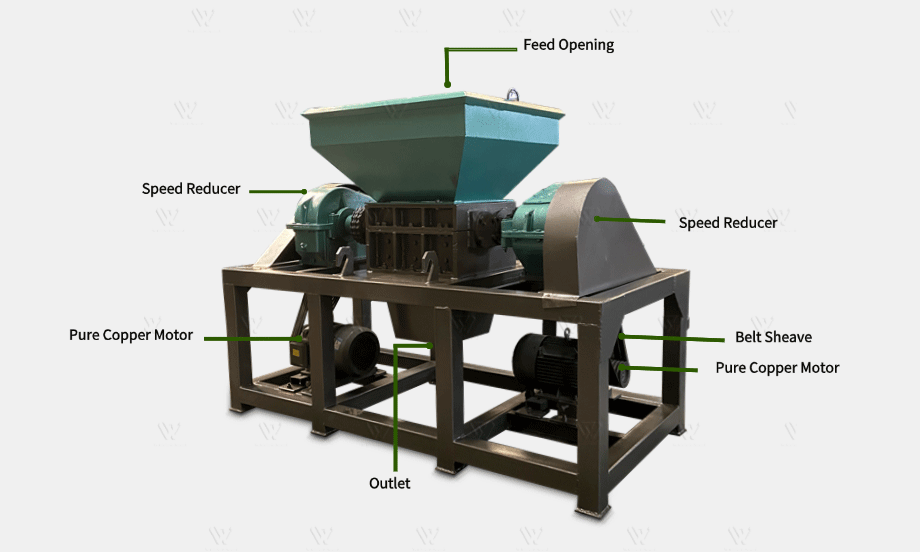

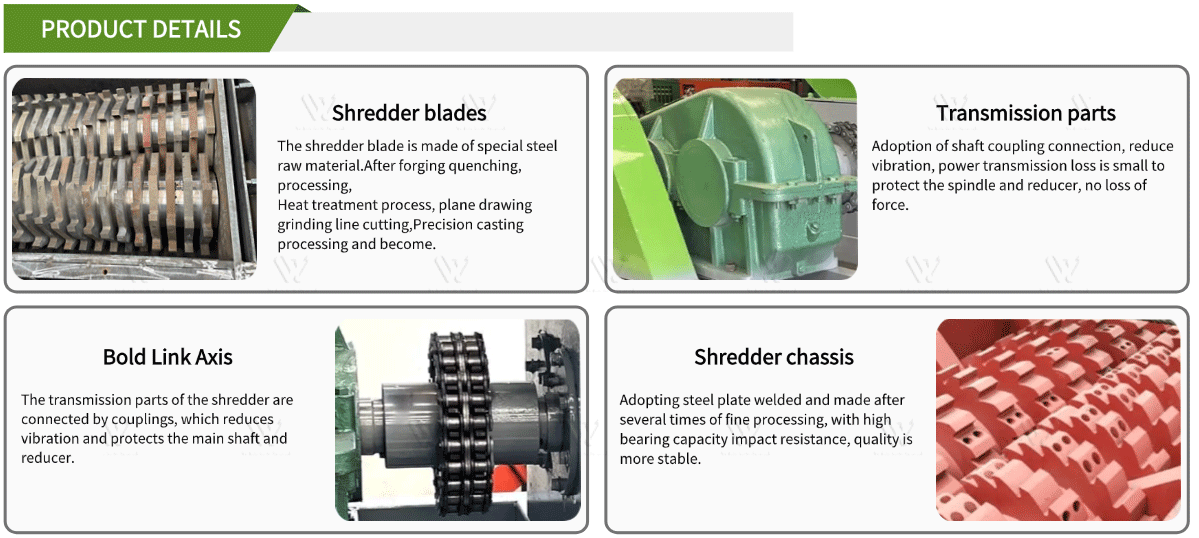

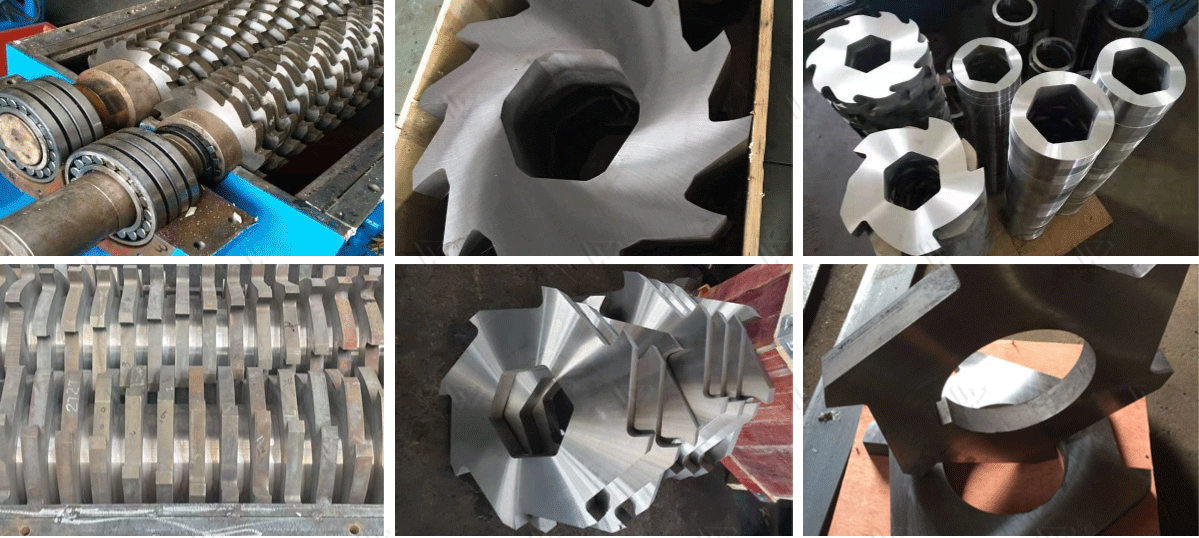

The multifunctional shredder adopts a microcomputer (PC) automatic control system, with start, stop, reverse and overload automatic reverse control functions, and has the characteristics of low speed, high torque, low noise, etc. The bearing seat adopts a split type, which is easy to disassemble and replace the blade, suitable for shredding extra large, extra thick and difficult to shred materials.

A large amount of scrap metal will be generated during the use of metal. If these scrap metals are discarded at will, it will cause serious environmental pollution and a great waste of resources. Therefore, recycling scrap metal resources for reuse can not only reduce the pollution of metal to the environment but also create considerable profits. The metal shredder provided by Wanshengda Machinery can solve this problem very well. It crushes the recycled scrap metal to reduce the volume, facilitate transportation, and facilitate production and reuse, thereby creating economic benefits for the enterprise.

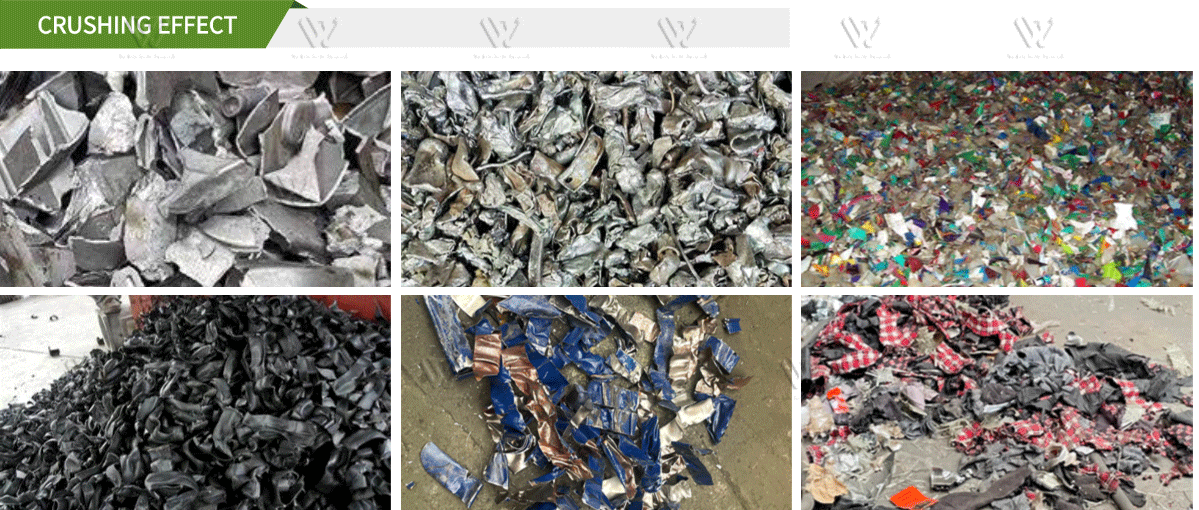

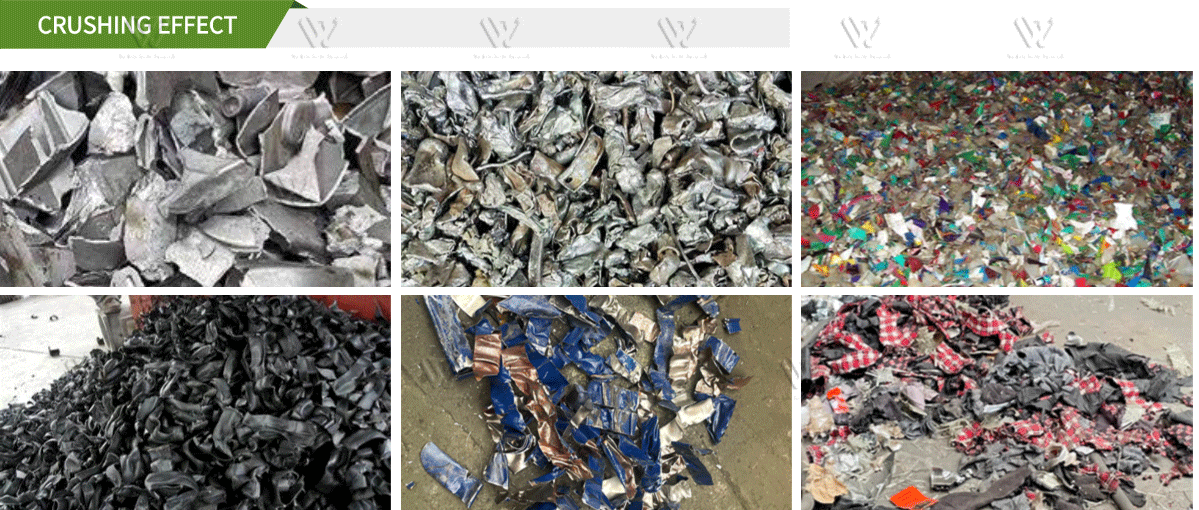

The materials that can be crushed by the metal shredder include: scrap metal, cans and bottles, scrap iron briquettes, scrap steel, scrap aluminum, scrap car shells, scrap building steel bars, scrap steel plates and other scrap metal materials.

When Wanshengda metal shredder equipment is working, the material can be fully coarsely crushed in the crushing chamber. High output, low energy consumption, high efficiency, and uniform discharging are the highlights of the equipment. When using this equipment, low noise, low pollution, simple operation and convenient maintenance are the characteristics of the metal shredder.

The main function of the metal shredder is to shred large pieces of scrap metal and scrap metal materials that are inconvenient to transport into sheet materials that meet the requirements through shearing and extrusion of the metal shredder. The metal shredder is carefully developed by making full use of shearing and extrusion theories. After years of research, the metal shredder equipment produced by Wanshengda Machinery is gradually being improved into a complete set of production line equipment, which is convenient for users' production and labor cost savings.

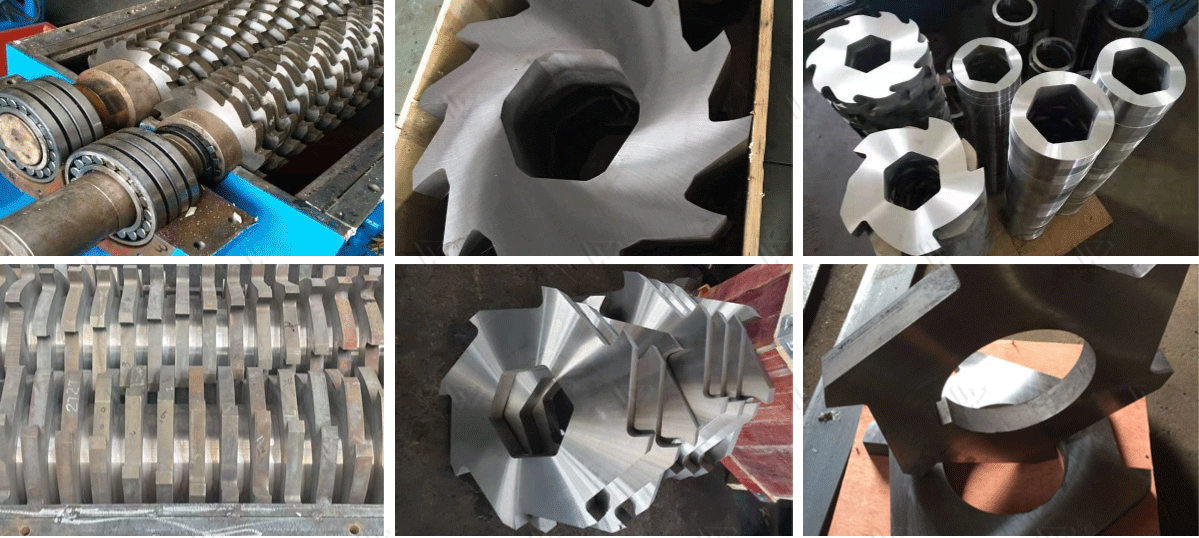

Tips: The fineness of the material can be adjusted according to the number of blades

Technical parameters:

| Model |

Spindle power (kw) |

Spindle speed (r/min) |

Output (t/h) |

Conveyor power (kw) |

Number of cutter discs (pieces) |

Cutter disc diameter (mm) |

Crushing particle size (cm) |

Binyard size (m) |

Length, width and height (m) |

Weight (t) |

| WSD-2600 |

4-160*2 |

16-18 |

25-60 |

4-3kw |

40 |

∅720 |

3-10 |

2.5*1.4 |

8.2*4*4.3 |

36 |

| WSD-1900 |

4-90*2 |

14-16 |

10-25 |

4-3kw |

40 |

∅560 |

3-10 |

2.3*2 |

8*2.5*2.4 |

15 |

| WSD-1500 |

4-45*2 |

14-16 |

8-18 |

4-3kw |

30 |

∅530 |

3-10 |

2*2 |

4*1.7*2.4 |

12 |

| WSD-1200 |

4-37*2 |

18-20 |

6-15 |

None |

28 |

∅372 |

3-10 |

1.4*1 |

3.2*2*1.9 |

6 |

| WSD-1000 |

4-30*2 |

18-20 |

5-10 |

None |

30 |

∅360 |

3-10 |

1.2*1 |

3*2*1.9 |

5 |

| WSD-600 |

4-15*2 |

18-20 |

2-5 |

None |

26 |

∅260 |

3-10 |

0.82*0.9 |

2.6*2*1.9 |

2.5 |