Product introduction

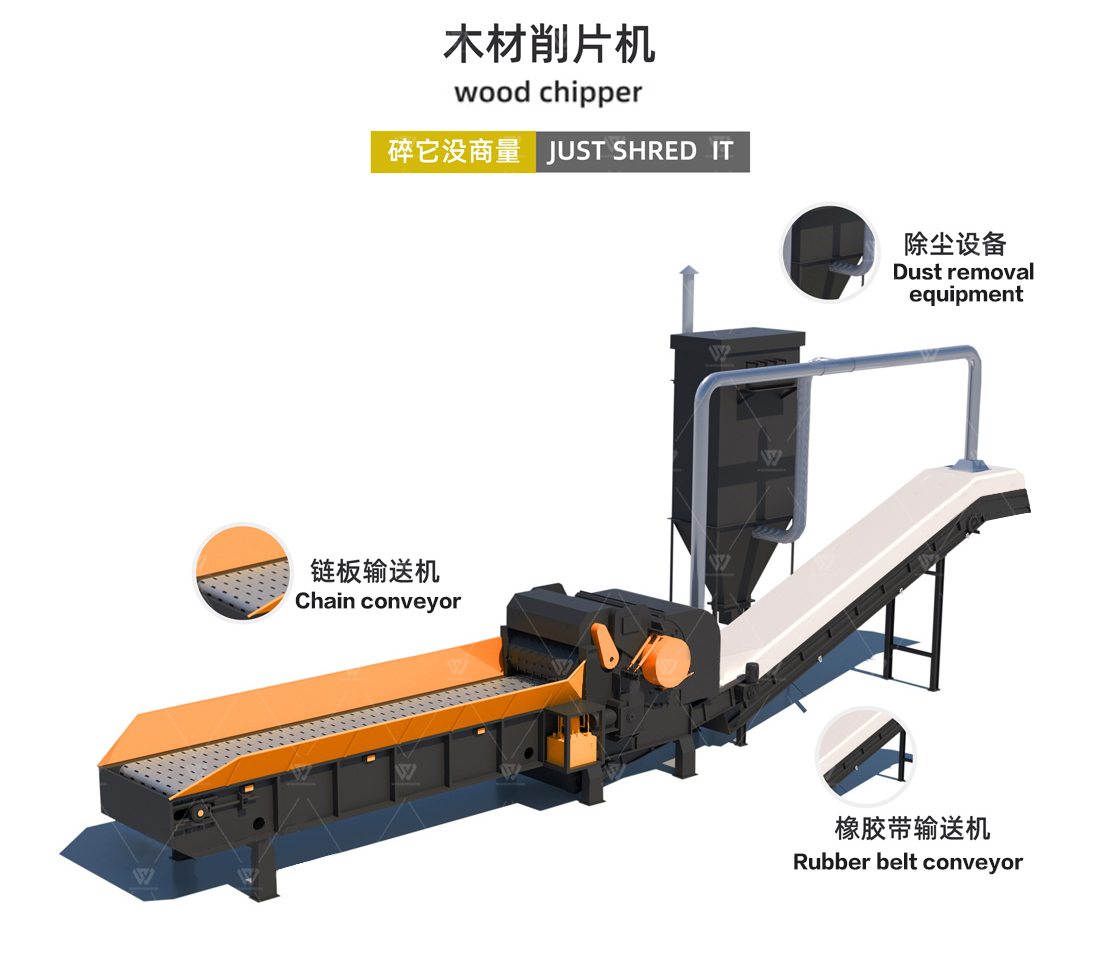

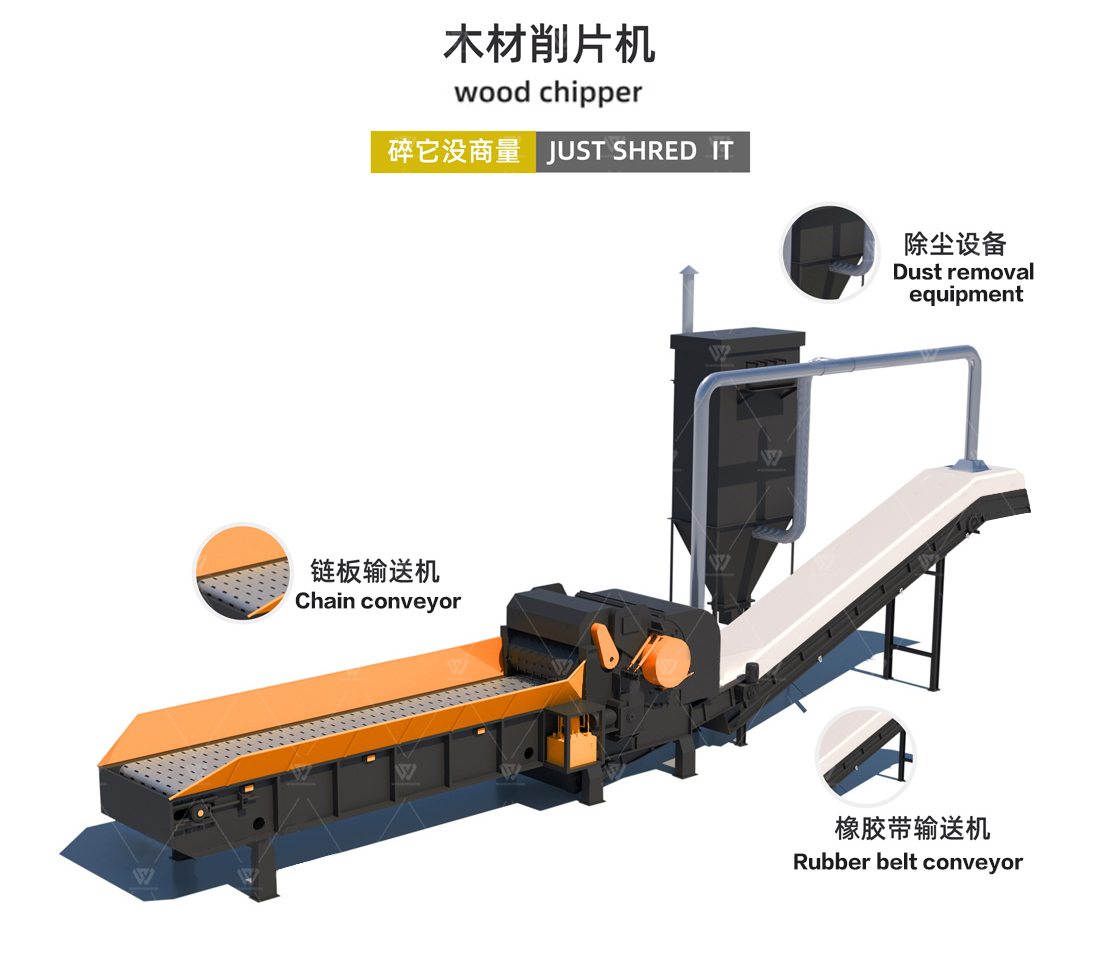

Wood chipper is a special equipment for producing wood chips. Wood chipper is also called wood slicer, which is one of the wood processing equipment series.

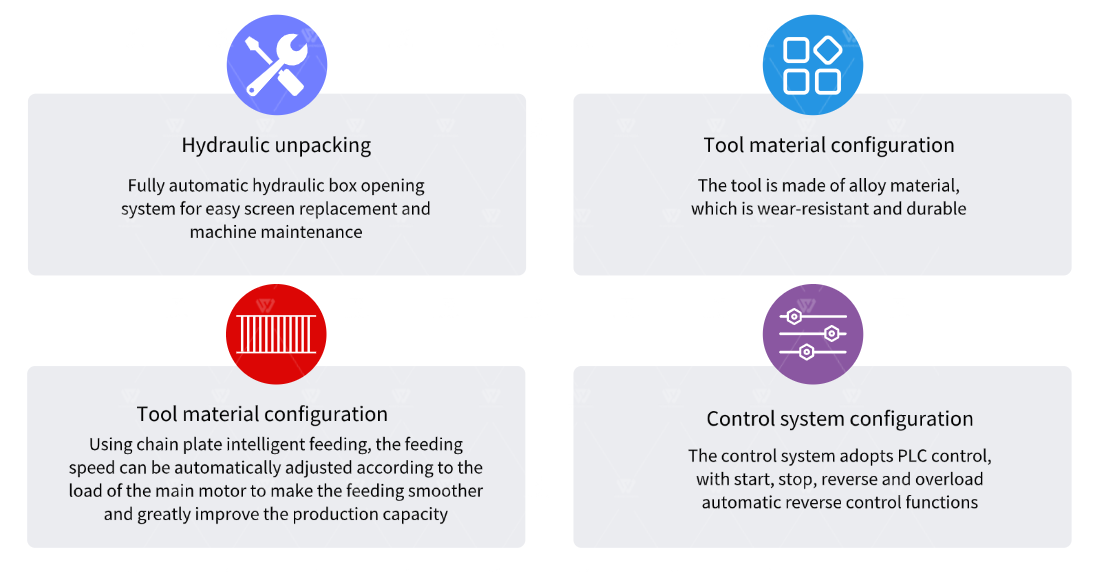

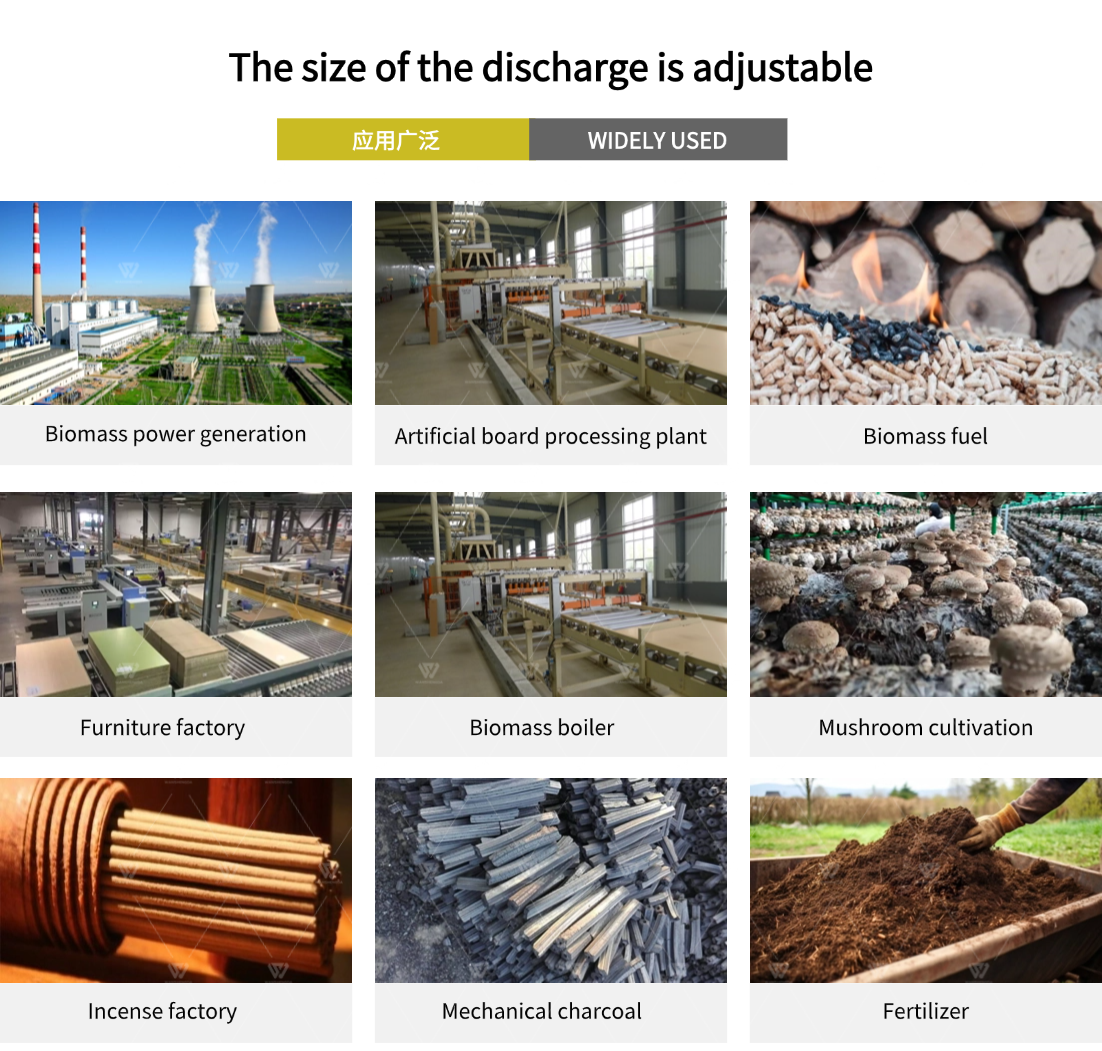

The integrated chipper is a new type of chipper, suitable for particleboard, medium density fiberboard, wood fiberboard, papermaking, power plants, boilers and other industries. This product has a high structure, high quality of cutting pieces, wide adaptability of raw materials, and is easy to operate and maintain.It is widely used in the material preparation section of the production process in the textile, papermaking, pulping, wood-based panel and other industries.

The integrated chipper is a new type of chipper, suitable for particleboard, medium density fiberboard, wood fiberboard, papermaking, power plants, boilers and other industries. This product has a high structure, high quality of cutting pieces, wide adaptability of raw materials, and is easy to operate and maintain.

If we use a wood chipper to process some waste logs, the processed materials can be reused. The processed waste wood can be used to produce artificial boards (such as particleboard, medium-density fiberboard, wood-plastic board, etc.). Artificial boards can replace solid wood in many uses.

The main raw materials for wood chippers are small-diameter wood, wood felling and processing residues (such as branches, twigs, board skin, laths, log cores, waste veneer, waste wood, etc.), and can also be used to cut non-wood materials (such as sugar cane, reeds, bamboo, etc.). Wood chippers have compact structure, reasonable layout, easy installation, convenient operation and maintenance, high production capacity, high quality wood chips when cutting logs, and the length of wood chips can be freely adjusted within the specified range.

When the wood chipper is working, the motor drives the rotor to rotate at high speed, and the wood evenly enters the integrated crusher cavity. The high-speed rotating hammer impacts, shears and tears the wood, causing the wood to be crushed. At the same time, the gravity of the wood itself causes the wood to rush from the high-speed rotating hammer to the baffle and screen bar in the frame. At the bottom of the rotor, there is a screen plate. The particles smaller than the size of the screen hole in the crushed wood are discharged through the screen plate, and the wood larger than the size of the screen hole is retained on the screen plate and continues to be hit and ground by the hammer.

| Model |

Feed size (mm) |

Motor power (kw) |

Feed power (kw) |

Discharge power (kw) |

Speed (r/min) |

Production efficiency (t/h) |

Dimensions (mm) |

| WSD-1000 |

1000*400 |

110 |

5.5*2 |

3 |

510 |

15-20 |

6000*2150*1750 |

| WSD-1300 |

1300*400 |

132 |

7.5*2 |

3 |

510 |

20-25 |

6000*2350*1750 |

| WSD-1500 |

1500*400 |

160 |

11*2 |

4 |

365 |

25-35 |

6000*2950*1950 |

| WSD-1600 |

1600*400 |

200 |

15*2 |

4 |

365 |

35-45 |

6000*2950*1950 |