Product Introduction

Feed particle size: 160-220mm

Production capacity: 43-398t/h

Application fields: mines, coal mines, recycling of garbage and construction waste, earthwork projects, urban infrastructure, road or construction site operations, etc.

Applicable materials: river pebbles, mountain stones (limestone, granite, basalt, diabase, andesite, etc.), ore tailings, and stone chips for artificial sand making.

The cone crusher equipped in the mobile cone crushing station is the Wanshengda high-performance hydraulic cone crusher, which features a hydraulic closed-side adjustment device and can produce aggregates of 10-45mm.The hydraulic closed-side adjustment device of the cone crusher is designed for quick and convenient adjustment of the crusher's settings. The adjustment is carried out through the control box, making this system very suitable for occasions where the discharge opening parameters need to be adjusted regularly.

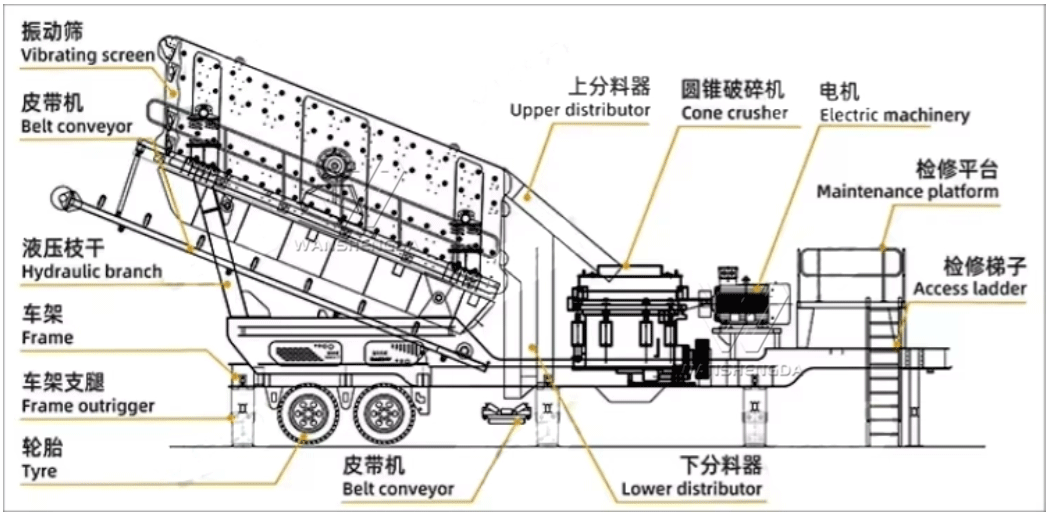

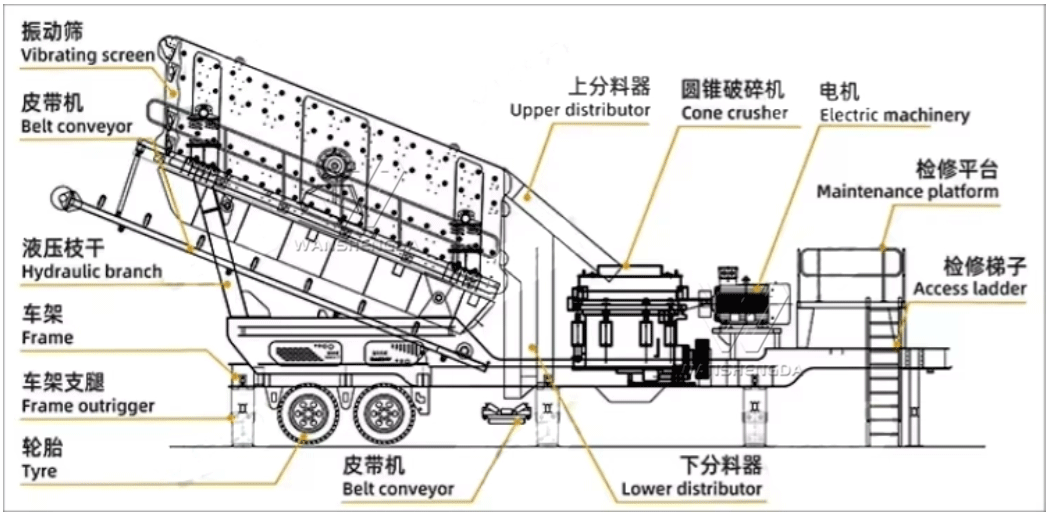

All components of the tire-mounted mobile cone crushing station are onboard, including: a sturdy frame, cone crusher, vibrating screen, conveyor, motor, control box, etc.

Materials are conveyed into the cone crusher via an external conveyor. After initial crushing by the cone crusher, a closed-circuit system is formed with the circular vibrating screen to realize cyclic crushing of materials. The finished materials are output by the belt conveyor for continuous crushing operations. The cone-type mobile crushing station can remove the circular vibrating screen according to actual production needs to directly perform initial crushing on materials. It is easy and flexible to operate when used in conjunction with other crushing equipment.

technical advantage

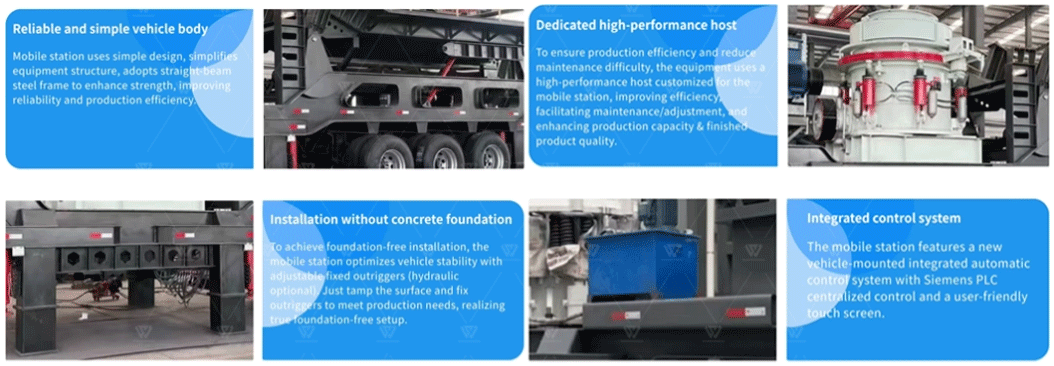

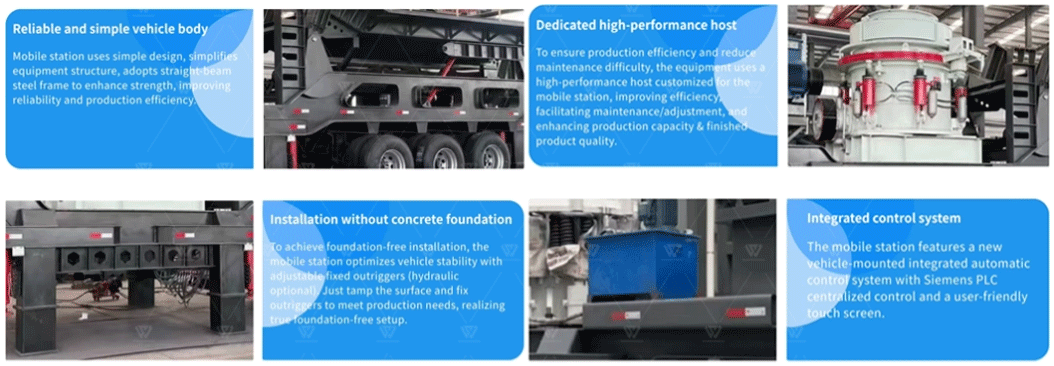

1.Good mobility, compact structure and easy operation 2.Cost saving and expense reduction

3.Higher applicability 4.Stable performance and convenient maintenance 5.Flexible configuration

The tire-mounted mobile cone crushing plant adopts mobile crushing technology, which can meet customers' mobile crushing requirements. It is mainly used for processing mobile stone materials in projects such as expressways, railways, and hydropower projects. Users can adopt various configuration forms according to the types of raw materials, production scale, and requirements for finished materials.

| Model |

WSD100JD |

WSD100SJD |

WSD200JD |

WSD200SJD |

WSD300JD |

WSD300SJD |

| Transport Dimensions |

| Length (mm) |

12790 |

13920 |

14323 |

14323 |

13920 |

13720 |

| Width (mm) |

3070 |

3070 |

3070 |

3070 |

3070 |

3070 |

| Height (mm) |

4370 |

4430 |

4460 |

4460 |

4450 |

4645 |

| Cone Crusher |

| Model |

JD100 |

JD100S |

JD200 |

JD200 |

JD300 |

JD300S |

| Maximum Feed Size (mm) |

90 |

200 |

145 |

300 |

175 |

400 |

| Discharge Opening Adjustment Range (mm) |

10-32 |

22-32 |

13-38 |

22-48 |

13-44 |

29-51 |

| Capacity (t/h) |

43-70 |

76-120 |

63-215 |

105-330 |

95-368 |

215-586 |

| Vibrating Screen |

|

| Model |

3KY1548 |

3KY1548 |

3KY1860 |

3KY1860 |

3YK2160 |

3YK2160 |

| Belt Conveyor |

|

| Model |

B800x7.5 |

B800x7.5 |

B1000x8.2 |

B1000x8.2 |

B1000x8.2 |

B1000x8.2 |

| Number of Axles |

2 |

2 |

2 |

2 |

3 |

3 |