Product introduction

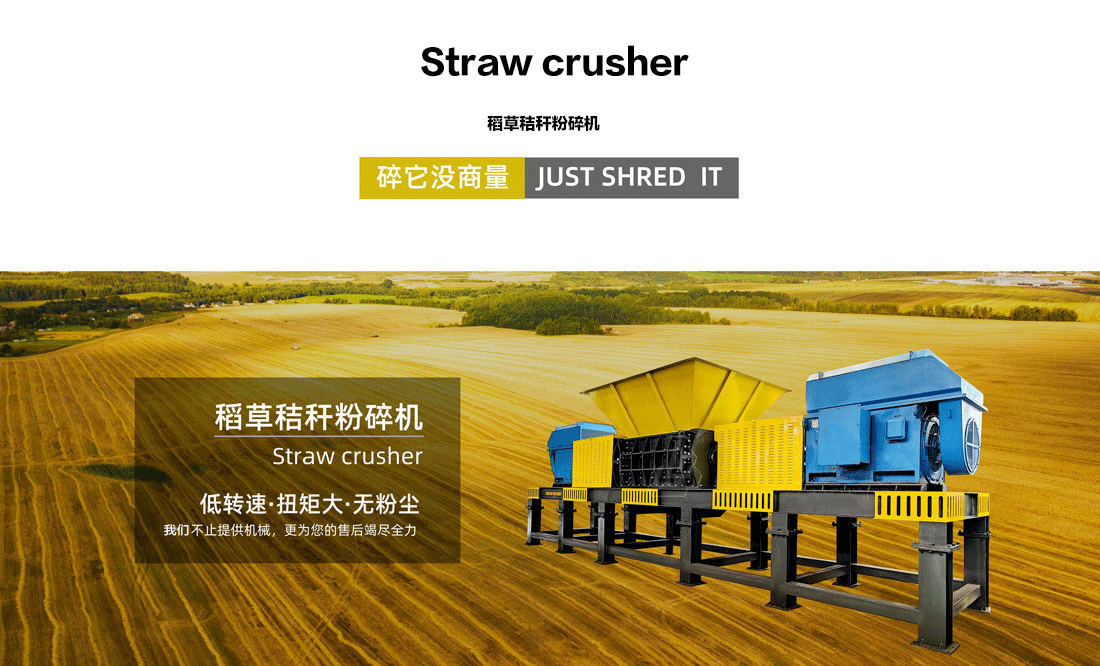

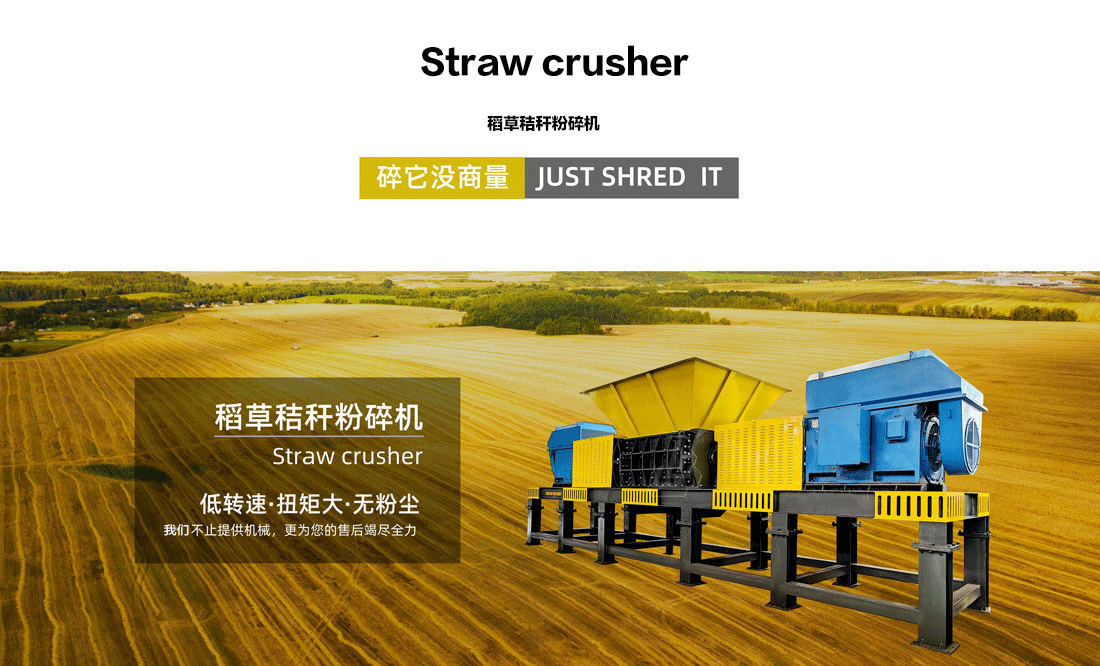

Biomass fuel, also known as biomass molded fuel, is a new type of clean fuel that uses biomass waste (such as straw, sawdust, bagasse, rice husk, etc.) as raw materials and can be directly burned after crushing. Compared with traditional fuels such as coal and liquefied gas, it not only has economic advantages but also has green energy-saving benefits, which meets the needs of sustainable development.The biomass power plant power generation project uses corn stalks, wheat stalks, pomegranate branches, and bark branches as the main fuel. The rice straw crusher has the characteristics of high density, concentrated and continuous, and easy collection and storage, which makes sufficient preparations for the energy utilization of straw.Applicable materials: Straw, corn stalks, peanut vines, wheat stalks, soybean stalks, cotton stalks, sugarcane, bark, boards, etc.

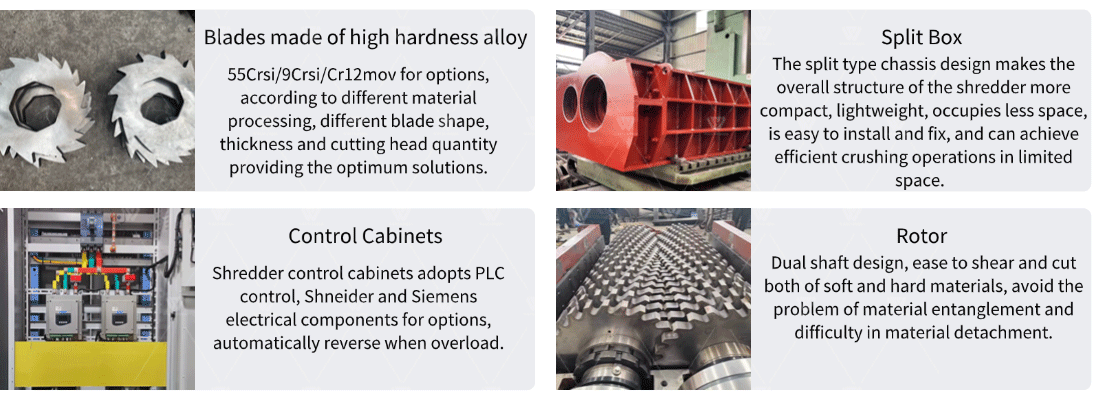

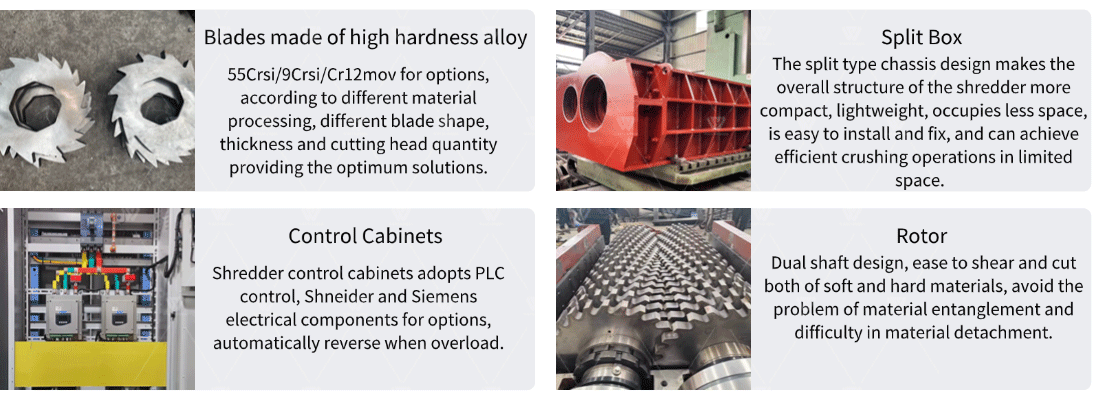

The crop straw is sent to the feeding port of the straw shredder through a conveyor and then to the crushing chamber. The double motor and reducer are directly connected to drive the double shafts in the crushing chamber (note: the double shafts are equipped with multi-tooth cutters) to perform rolling, shearing, squeezing and other methods to crush the materials. The crushed materials are then conveyed to the collection site. The whole process is both environmentally friendly and energy-saving. It is a modern straw crushing equipment with high efficiency, high output and stable operation.

Bundles of straw go along the chain conveyor and are processed into small-particle fuel through multiple processes such as crushing and granulation. After being crushed, the straw is burned in the furnace, and the chemical energy is converted into thermal energy, and the thermal energy is converted into kinetic energy, generating steam to drive the turbine to "produce" electricity and send it into the power grid.

The rice straw crusher is environmentally friendly and energy-saving. It is a modern straw crushing equipment with high efficiency, high output and stable operation.The rice straw crusher realizes automatic lubrication, intelligent detection and abnormal alarm. The PLC touch screen control cabinet or mobile client can monitor the equipment operation status in real time and fully automatically control the feeding speed of the chain conveyor.

The key components of the rice straw crusher are all made of imported high-quality alloy forgings. After the heat treatment process, they have high strength and longer service life than domestic ones. The frame structure is strong, with greater strength and high stability.

| Model |

Spindle power (kw) |

Spindle speed (r/min) |

Output (t/h) |

Conveyor power (kw) |

Number of cutter discs (pieces) |

Cutter disc diameter (m/m) |

Crushing size (am) |

Binyard size (m) |

Length, width and height (m) |

Weight (t) |

| WSD-2600 |

4-160*2 |

16-18 |

25-60 |

4-3kw |

40 |

Ø720 |

3-10 |

2.5*14 |

8 2*4*4 3 |

36 |

| WSD-1900 |

4-90*2 |

14-16 |

10-25 |

4-3kw |

40 |

Ø560 |

3-10 |

23*2 |

8*2.5*2.4 |

15 |

| WSD-1500 |

4-45*2 |

14-16 |

8-18 |

4-3kw |

30 |

Ø530 |

3-10 |

2*2 |

4*1.7*2.4 |

12 |

| WSD-1200 |

4-37*2 |

18-20 |

6-15 |

None |

28 |

Ø372 |

3-10 |

14*1 |

3.2*2*1.9 |

6 |

| WSD-1000 |

4-30*2 |

18-20 |

5-10 |

None |

30 |

Ø360 |

3-10 |

1.2*1 |

3*2*19 |

5 |

| WSD-600 |

4-15*2 |

18-20 |

2-5 |

None |

26 |

Ø260 |

3-10 |

0.82*0.9 |

2.6*2*1.9 |

2.5 |