Product introduction

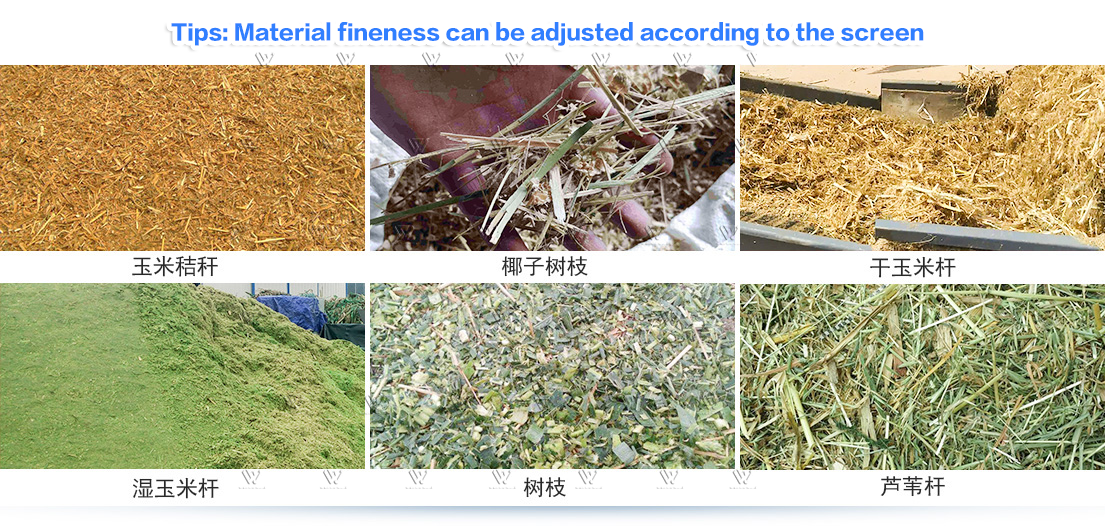

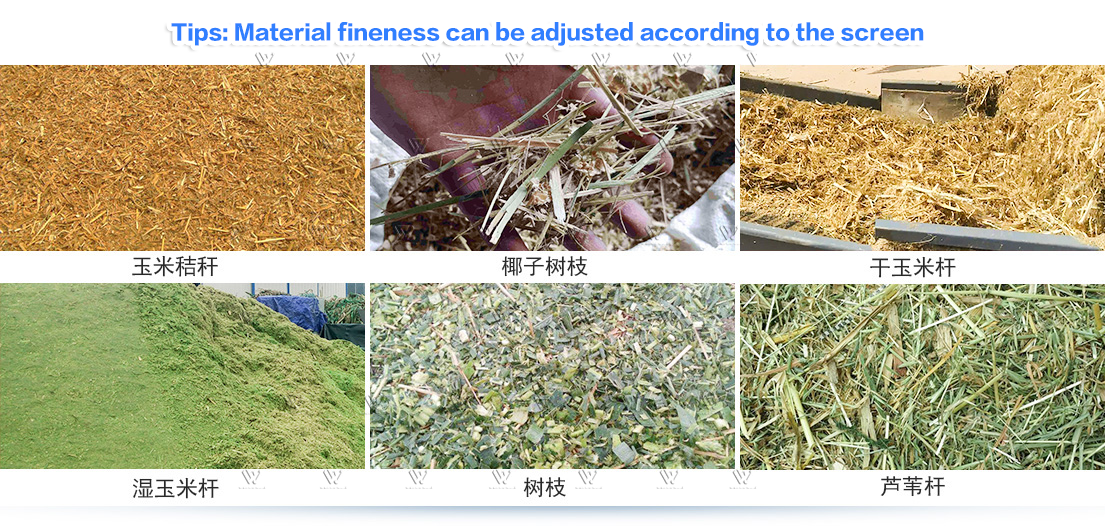

The Agricultural Straw Crushe can crush corn stalks, rice straw bales, wheat straw, bean stalks and other combustible crop waste stalks, avoiding the wasteful burning of these crop straws, protecting the environment well, and greatly expanding the utilization rate of energy.

Agricultural Straw Crushe is a large-scale agricultural equipment with a wide range of products. It is widely used in crushing crops such as straw, rice straw, cotton stalks, wheat stalks, eucalyptus bark, forage grass, bean stalks, corn stalks, etc.The crushed materials are supplied to: large-scale livestock breeding feed, large-scale biomass power plant power generation, large-scale biomass pellet fuel plants, etc.

1. Crusher body

The main body of the equipment is machined by welding high-quality steel plates to ensure the stability of the equipment under long-term heavy loads.

2. Moving knife/fixed knife

The moving knife material is made of special alloy tool steel forging blanks, precision machining, multiple heat treatments and low-temperature freezing heat treatment technology. The overall toughness and hardness are consistent and can be repeatedly repaired and used to ensure cutting performance and service life. The fixed knife is installed in a hook-type manner to optimize the tool replacement function and make tool maintenance and replacement more convenient.

3. Bearing/Seal

The bearing seat is easy to disassemble by splicing, and the unique sealing structure effectively blocks the contact between crushed objects and grease. It can also protect bearings and gears when handling liquid materials.

4. Knife shaft

It is made of high-strength and heavy-duty special steel and more reasonably matches the knife to provide powerful power for shearing.

The straw crusher adopts a combined blade structure and is a device that crushes materials in a mixed manner of impact, extrusion and shearing. The main components of the wheat straw crusher include: a frame, a feed box arranged above the frame, and a pair of motors arranged on the frame.

| Model |

Spindle power (kw) |

Spindle speed (r/min) |

Output (t/h) |

Conveyor power (kw) |

Number of cutter discs (pieces) |

Cutter disc diameter (m/m) |

Crushing size (am) |

Binyard size (m) |

Length, width and height (m) |

Weight (t) |

| WSD-2600 |

4-160*2 |

16-18 |

25-60 |

4-3kw |

40 |

Ø720 |

3-10 |

2.5*14 |

8 2*4*4 3 |

36 |

| WSD-1900 |

4-90*2 |

14-16 |

10-25 |

4-3kw |

40 |

Ø560 |

3-10 |

23*2 |

8*2.5*2.4 |

15 |

| WSD-1500 |

4-45*2 |

14-16 |

8-18 |

4-3kw |

30 |

Ø530 |

3-10 |

2*2 |

4*1.7*2.4 |

12 |

| WSD-1200 |

4-37*2 |

18-20 |

6-15 |

None |

28 |

Ø372 |

3-10 |

14*1 |

3.2*2*1.9 |

6 |

| WSD-1000 |

4-30*2 |

18-20 |

5-10 |

None |

30 |

Ø360 |

3-10 |

1.2*1 |

3*2*19 |

5 |

| WSD-600 |

4-15*2 |

18-20 |

2-5 |

None |

26 |

Ø260 |

3-10 |

0.82*0.9 |

2.6*2*1.9 |

2.5 |