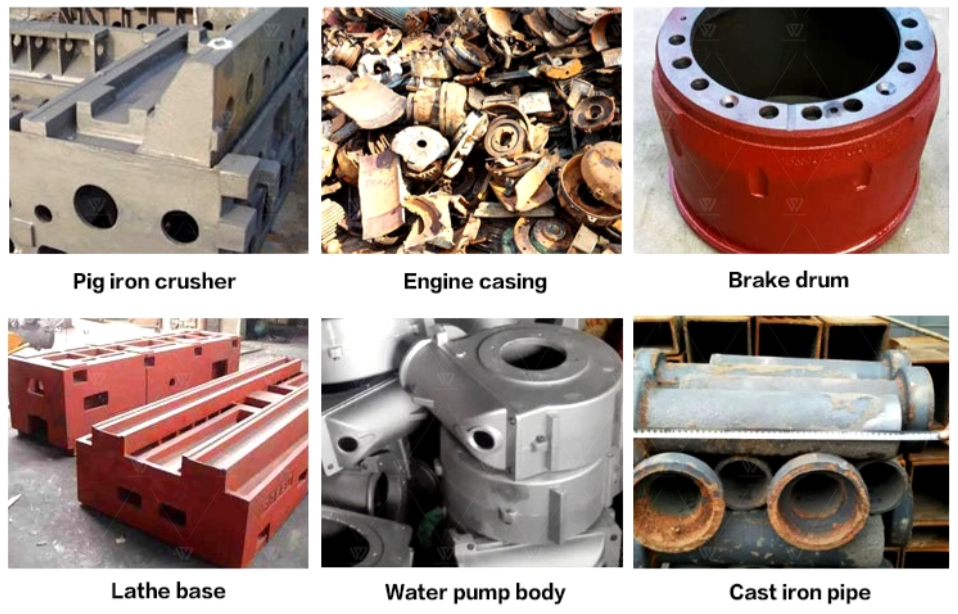

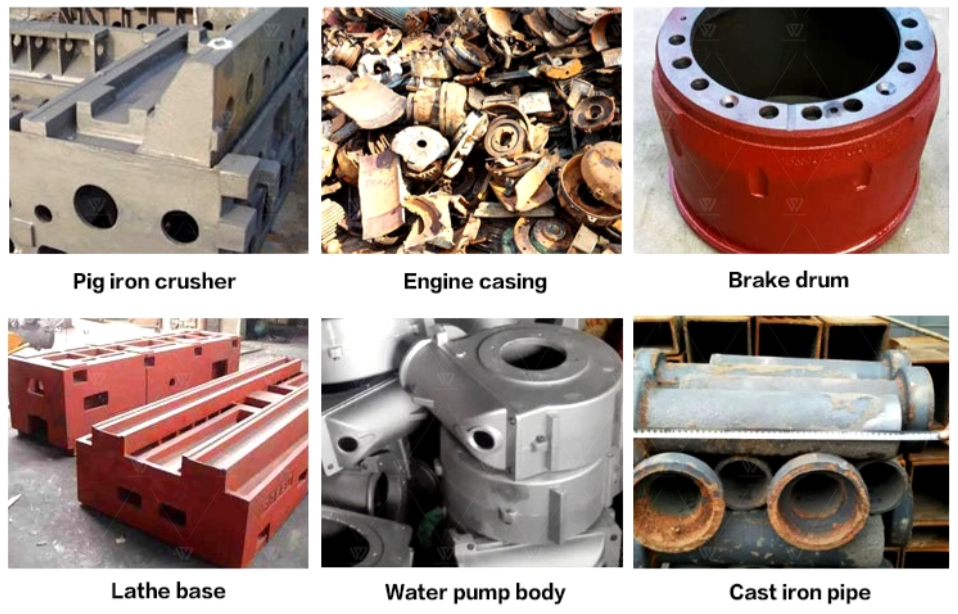

(2) (6).png) The types of pig iron crusher that can crush include: large pieces of scrap pig iron, returned iron, machine iron, malleable cast iron, billet iron, ferroalloys, silicon-containing materials, aluminum alloys, large cast iron returned materials, billet molds, engine bodies, cylinder bodies, scrap pig iron castings, scrap machine iron, etc. into small pieces of pig iron, which is convenient for feeding into the furnace and recycling casting processing. It is an ideal crushing equipment for foundries and large and medium-sized steel mills.

The types of pig iron crusher that can crush include: large pieces of scrap pig iron, returned iron, machine iron, malleable cast iron, billet iron, ferroalloys, silicon-containing materials, aluminum alloys, large cast iron returned materials, billet molds, engine bodies, cylinder bodies, scrap pig iron castings, scrap machine iron, etc. into small pieces of pig iron, which is convenient for feeding into the furnace and recycling casting processing. It is an ideal crushing equipment for foundries and large and medium-sized steel mills.

The pig iron crusher works in a kinetic extrusion type, and its working principle is: the hydraulic lever controls the forward and backward movement of the movable jaw. When the movable jaw moves forward, it approaches the fixed jaw plate, and at the same time, the material is crushed or split to achieve the purpose of crushing; when the movable jaw moves backward, the angle between the liner and the movable jaw becomes smaller, and the movable jaw leaves the fixed jaw plate. At this time, the crushed material is discharged from the lower opening of the crushing chamber.

Product Features:

1. Low noise and less dust.

2. Its crushing ratio is large and the product particle size is uniform.

3. Simple structure, reliable operation and low operating costs.

4. The lubrication system is safe and reliable, parts are easy to replace, and equipment maintenance is simple.

5. The crushing chamber is deep and has no dead zone, which improves the feeding capacity and output.

6. Equipment energy saving: single machine energy saving is 15% to 30%, and the system energy saving is more than doubled.

7. The discharge port has a large adjustment range to meet the requirements of different users.

Technical parameters:

| Model |

Crushing chamber size (mm) |

Processing capacity (T/D) |

Power (kw) |

Weight (kg) |

| WST350 |

1300*1400 |

60-80 |

22 |

15000 |

| WST500 |

1400*1600 |

100-150 |

30*2 |

22000 |

| WST800 |

1600*2000 |

200-300 |

37*2 |

34000 |

.png)

.png)

(2) (6).png)

.png)

.png)