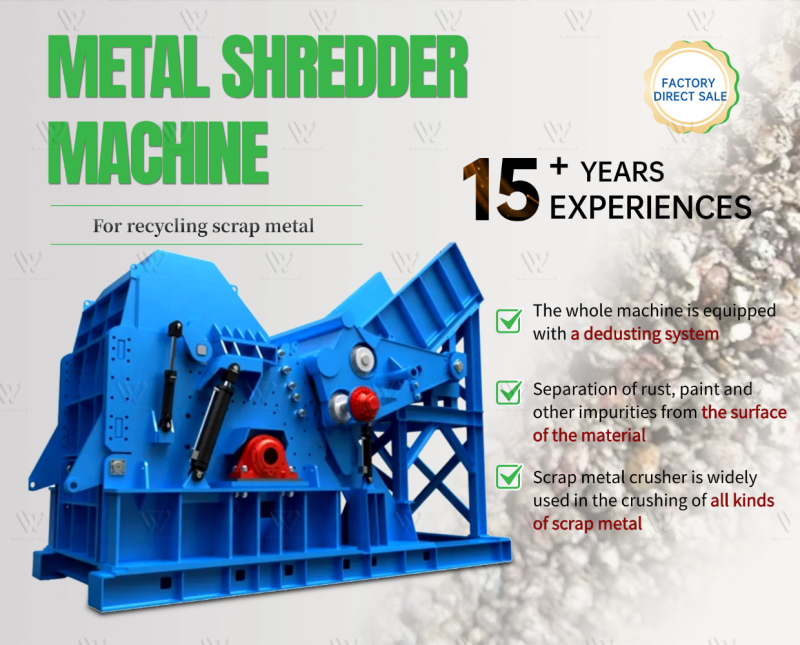

Metal Crusher Introduction

Metal crusher is also called metal shredder, can crusher, paint barrel crusher, scrap crusher, color steel tile crusher, bicycle

crusher, iron box crusher, scrap aluminum crusher, scrap iron crusher, block crusher, etc. It can not only crush all kinds of

beverage cans, paint barrels, oil tanks, but also crush waste bicycles, motorcycles, car shell, waste steel and iron sheets. As long as the metal can be crushed, the crushed materials are very easy to carry and transport, which is convenient for feeding and steelmaking.

Working Principle:

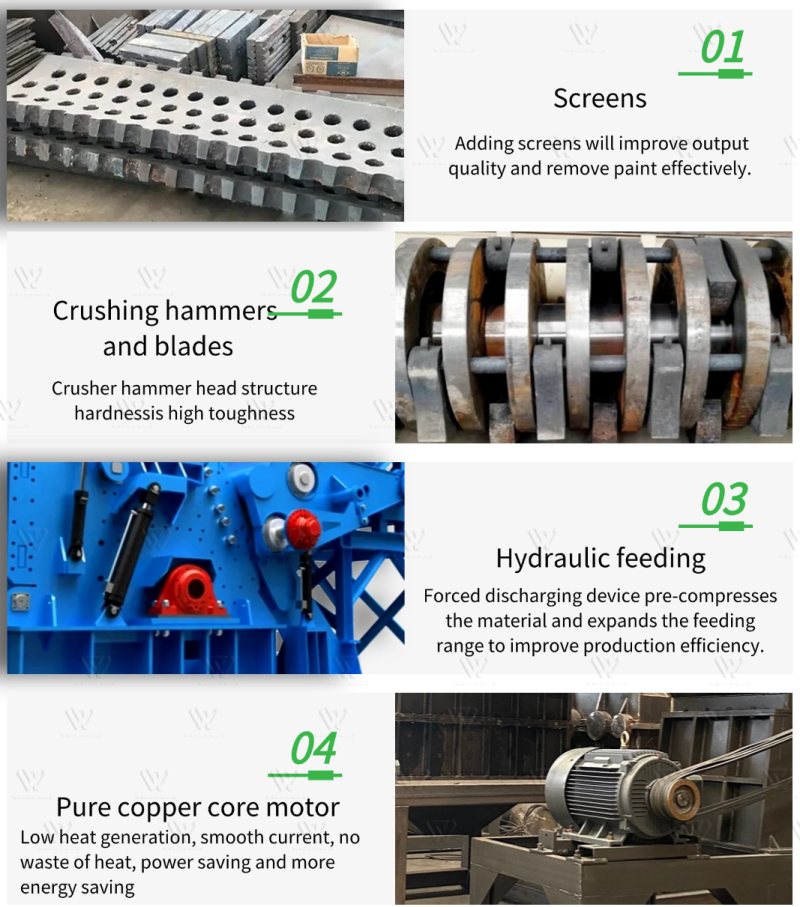

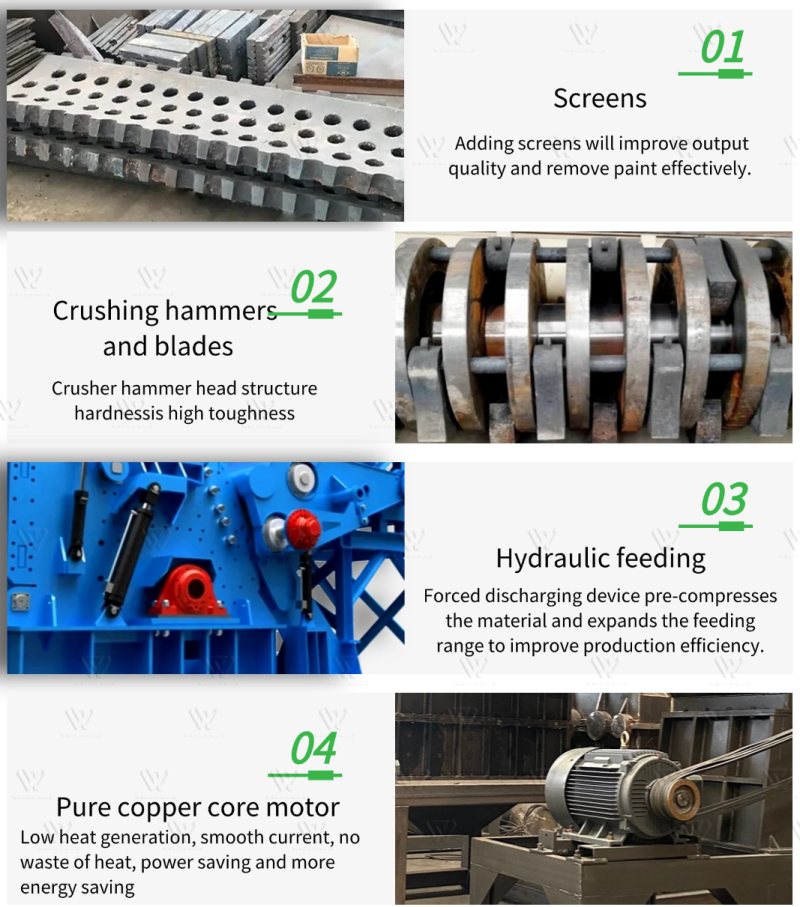

In terms of equipment structure, the main body shell is made of extra-thick steel plate, and the inner lining is high-manganese cast steel to protect the outer body. Using the hammer striking effect, driven by a high-speed, high-torque motor, the hammer heads on the main body rotor strike the objects to be crushed in the cavity in turn, and the objects to be crushed are broken into crushed materials that meet the specifications through the space formed between the lining plate and the hammer heads. Then, under the action of the magnetic device, high-purity high-quality crushed materials can be obtained.

Applicable materials: waste iron cans, motorcycle frames, bicycle frames, waste home appliances, automobile shells, carriages, plates, keel strips, paints, coatings, etc.

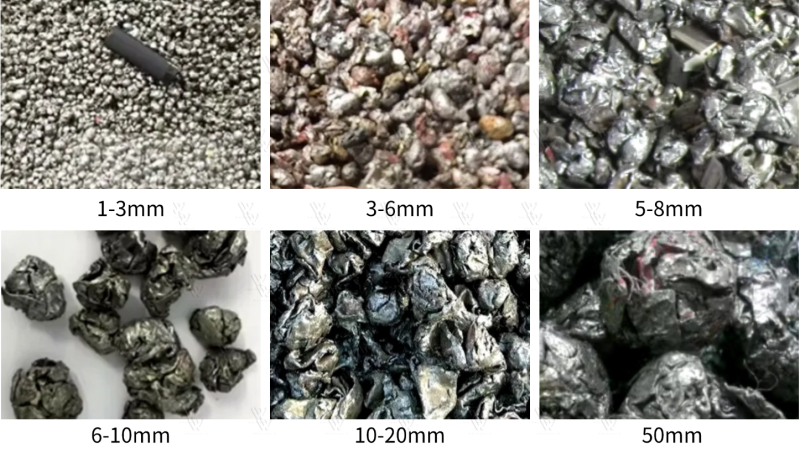

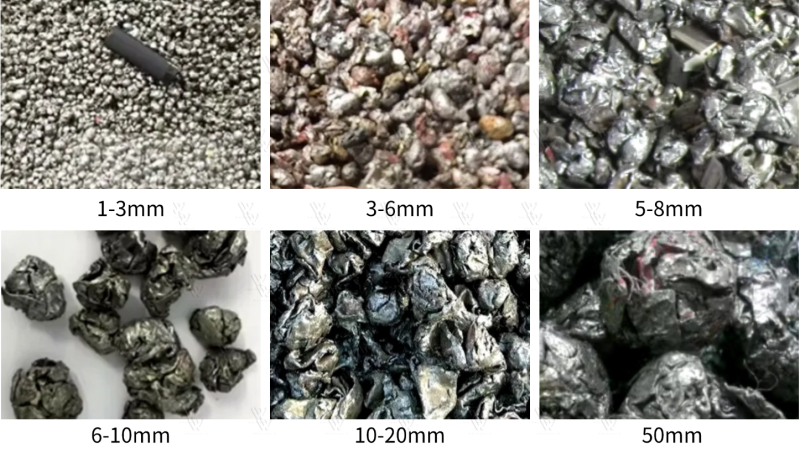

Diameter of crushed particles

Note: The above parameters are for reference only. The equipment technology changes caused by technical updates and product design changes will not be notified separately.

| Model |

Power |

Speed |

Processing capacity (t/h) |

Dimensions (mm) |

Weight (t) |

| WS-PS800 |

37-55 |

1250 |

0.7-1 |

3800*1600*1800 |

3.2 |

| WS-PS1000 |

45-75 |

1250 |

0.8-1.5 |

2560*1800*2200 |

7.6 |

| WS-PS1300 |

90-150 |

860 |

2-4 |

4000*3500*3200 |

11.5-26 |

| WS-PS1600 |

200-280 |

750 |

4-6 |

4800*4000*3800 |

16.6-35 |

| WS-PS1800 |

220-450 |

650 |

6-10 |

4800*4100*4000 |

32-48 |

| WS-PS2000 |

315-630 |

650 |

8-12 |

5000*4500*4300 |

35-65 |

| WS-PS2200 |

500-900 |

650 |

15-20 |

5000*4500*4300 |

35-65 |

| WS-PS2400 |

1250-2250 |

650 |

20-45 |

6300*4800*4500 |

85-120 |

| WS-PS2800 |

1600-3300 |

650 |

70-100 |

6400*5200*4800 |

145-230 |

| WS-PS3000 |

3300-4400 |

650 |

110-140 |

8500*7200*5500 |

280-760 |

The basic equipment of the metal crushing production line includes: feeding chain conveyor, double roller roller, crusher, vibrating conveyor, magnetic separator, and discharging belt conveyor. In addition, if non-ferrous metal separation is required, it is equipped with a non-ferrous metal separator; if wind separation is required, a wind separation system can be installed; if dust removal is required, a dust removal system is installed, etc.