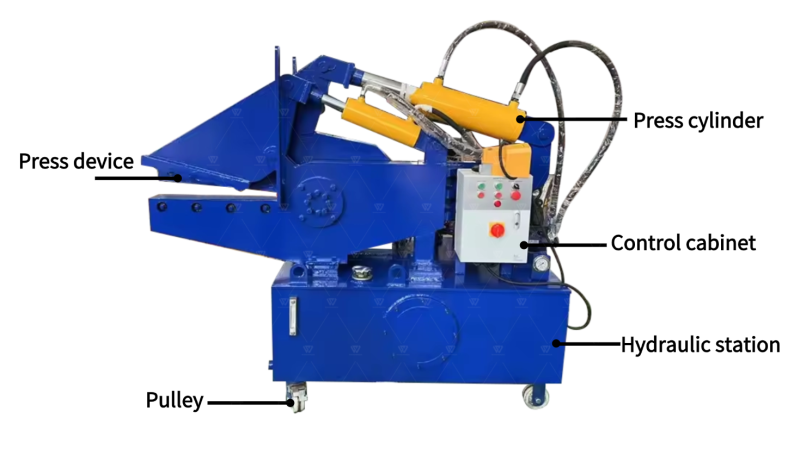

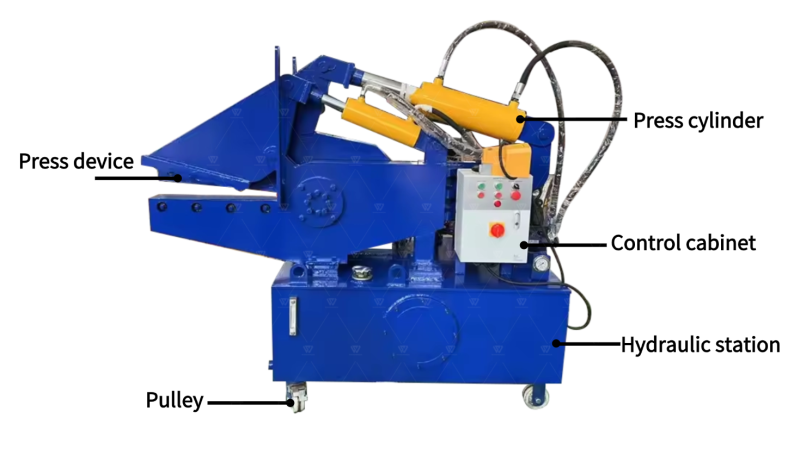

Crocodile Iron Shears Hydraulic Steel Shearing Machine/ Series Alligator Scrap Metal Shears

Alligator shears are suitable for scrap metal recycling plants, scrap car dismantling yards, smelting and casting industries. They are mainly used in the scrap material recycling and processing industry and small and medium-sized steel mills for cold shearing and cutting of scrap metals with various cross-sectional shapes such as round steel, square steel, channel steel, angle steel, I-beam, steel plate, steel pipe, etc.

.png)

.png)

Alligator shearing machine is also called crocodile shear, which is composed of shearing cylinder, shearing knife, slider pressing knife, lower knife seat, pressing cylinder, etc. When shearing is in operation, the hydraulic pump station (power output source) supplies oil to the pressing cylinder to push the slider pressing knife onto the lower knife seat to complete the fixed pressing of the material, and then the hydraulic pump station supplies oil to the shearing cylinder to make the shearing knife move downward to complete the shearing step. After shearing is completed, the hydraulic pump station completes the return action under the hydraulic oil reflux drive of the shearing cylinder and the pressing cylinder.

1.Hydraulic drive is adopted, which is easy to operate and maintain.

2.The shearing force of the working blade ranges from 63 tons to 500 tons in 9 levels.

3.Compared with the mechanical transmission shearing machine, it has the advantages of small size, light weight, small inertia, low noise, smooth movement, convenient and flexible operation, large shearing section, easy adjustment of the scissors, etc. It is safe to operate and use, and easy to achieve overload protection.

| Model |

Shearing force (KN) |

Pressing force (KN) |

Blade length (MM) |

Opening (MM) |

Number of cuts per minute |

Main cut material Dimensions (MM) |

Total machine power (KW) |

| WSJ63 |

630 |

160 |

600 |

280 |

10-12 |

30X30 Ø35 |

7.5 |

| WSJ100 |

1000 |

160 |

800 |

280 |

10-12 |

40X40 Ø45 |

11 |

| WSJ125 |

1200 |

200 |

1000 |

280 |

10-12 |

45X45 Ø50 |

15 |

| WSJ160 |

1600 |

250 |

1000 |

320 |

10-12 |

55X55 Ø63 |

18.5 |

| WSJ200 |

2000 |

250 |

1200 |

380 |

8-10 |

65X65 Ø75 |

22 |

| WSJ250 |

2500 |

300 |

1200 |

480 |

8-10 |

70X70 Ø80 |

30 |

| WSJ315 |

3150 |

420 |

1200 |

520 |

8-10 |

80X80 Ø90 |

37 |

| WSJ400 |

4000 |

420 |

1400 |

680 |

6-8 |

90X90 Ø100 |

44 |

| WSJ500 |

5000 |

550 |

1600 |

680 |

6-8 |

100X100 Ø110 |

60 |

.png)

.png)