The hydraulic standby machine is mainly suitable for waste paper, waste cartons, woven bags, plastic film, plastic bottles, waste newspapers, hydrophobic, cotton, thin fabrics, clothes, domestic garbage, etc. It is an essential production tool for light industrial enterprises such as waste material recycling industry, cotton producing areas, textile enterprises, supermarkets, garment factories, etc. It greatly reduces the volume, thereby reducing the transportation volume, saving freight, and reducing the transportation volume for the enterprise.

.png)

.png)

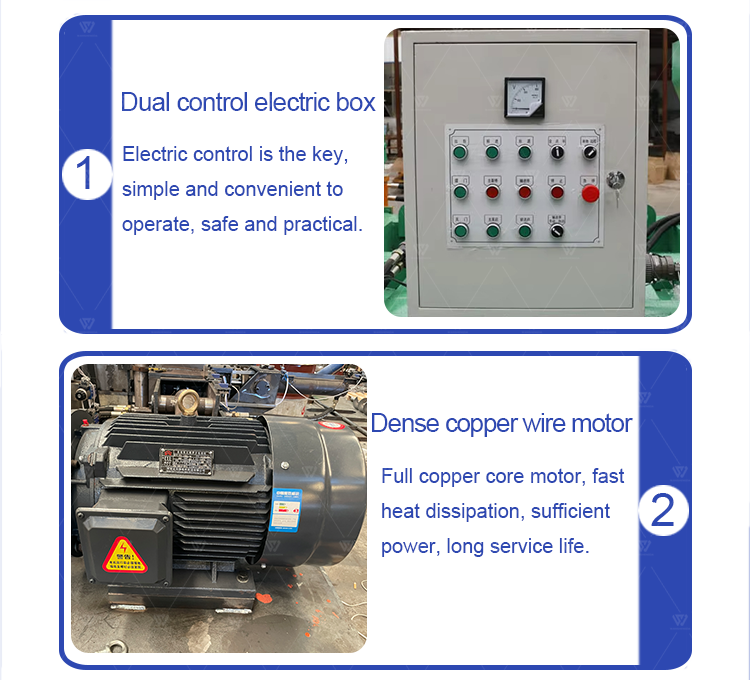

1. Unmanned, fully automatic, improve efficiency and save manpower.

2. The feeding port can be connected to the conveyor belt for feeding, which is suitable for waste cartons, plastics, cloth and large garbage disposal places.

3. Unique strapping device, fast speed, simple structure, stable action, low failure rate and easy maintenance.

4. The international standard circuit layout, graphical operation instructions and detailed component labeling are easy for the operator to understand and improve maintenance efficiency.

5. The length of the package can be set freely, and the packing value can be accurately recorded, which is convenient for the operator.

.png)

.png)

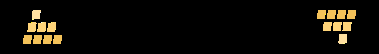

1. The hydraulic oil circuit power system is adopted, which improves the packaging efficiency, and has the characteristics of fast packing speed, high efficiency, energy saving and power saving, and stable performance.

2. A variety of cooling systems are available for users to choose (water cooling system, air cooling system and industrial air conditioning cold system), among which industrial air conditioning and refrigeration is a high-tech achievement in our company's baler industry;

3. It adopts two fast and efficient bundling methods, push and hook, fast and efficient bundling device, low failure rate and easy maintenance;

4. Using the principle of mechanics, 3 sets of tight oil cylinders make the compressed material compressed more tightly, and the packaged package shape is more regular and the density is larger;

5. Touch screen console, microcomputer PLC control, simple, clear, clear at a glance, and with computer-aided error correction function;

6. The double-toughness cutter design is adopted, which greatly improves the cutting efficiency and prolongs the service life of the blade.

| Model |

WY-100 |

WY-120 |

WY-160 |

WY-180 |

WY-200 |

| Nominal pressure |

1000KN |

1200KN |

1600KN |

1800KN |

2000KN |

| Number of bundles(strip) |

4 |

4 |

5 |

5 |

5 |

| Strapping method |

Manual/Automatic |

Manual/Automatic |

Manual/Automatic |

Manual/Automatic |

Manual/Automatic |

| Package size |

1100mm×850mm×1300mm Adjustable |

1100mm×850mm×1300mm Adjustable |

1100mm×1250mm×1700mm Adjustable |

1100mm×1250mm×1700mm Adjustable |

1100mm×1250mm×2000mm Adjustable |

| System pressure |

25mpa |

25mpa |

25mpa |

25mpa |

25mpa |

| Voltage/frequency |

380V/50HZ |

380V/50HZ |

380V/50HZ |

380V/50HZ |

380V/50HZ |

| How it works |

Automatic/Manual |

Automatic/Manual |

Automatic/Manual |

Automatic/Manual |

Automatic/Manual |

| Yield |

6~9 bags/H |

6~9 bags/H |

6~9 bags/H |

6~9 bags/H |

6~9 bags/H |

| Bulk weight (kg) |

400-600kg/bags |

700-900kg/bags |

1000-1300kg/bags |

1100-1500kgbags |

1200-1600kg/bags |

.png)

.png)

.png)

.png)

.png)

.png)