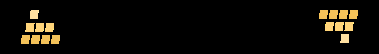

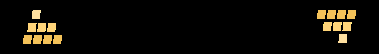

Vertical hydraulic baler is used for compressing and baling loose materials. It uses hydraulic drive to compress compressible resources to reduce the volume and form a whole. The bale has high density and uniform size. It is packaged with wire or strapping tape.

.png)

The machine adopts hydraulic transmission, compact structure, easy to transfer, simple operation, easy maintenance, reliable sealing, and no foot screws are used for installation. The user can customize the specifications and size of the briquetting according to the needs to cooperate with the transportation or storage to the greatest extent, which is a good equipment to improve labor efficiency, reduce labor intensity, save manpower and reduce transportation costs.

It is widely used in the compression and packaging of all loose materials such as waste paper, plastic bottles, plastic film, cotton, clothing, woven bags, cotton yarn, waste cotton, cloth, waste cloth, sacks, wool balls, straw, forage, tobacco leaves, hops, metal processing thin materials, etc. It effectively reduces the storage space, increases density, improves logistics efficiency, reduces transportation losses, greatly reduces freight, and beautifies the office and production environment. At the same time, it reduces labor intensity and improves work efficiency. It is an ideal choice for various manufacturing factories, material recycling stations, and renewable resource recycling companies..png)

| Model |

Power (kw) |

Bale size (mm) |

Bale weight (kw) |

Output (bales/hour) |

| YG81-10 single cylinder |

5.5 |

800*400*800 |

50 |

6-8 |

| YG8120 single cylinder |

5.5 |

800*400*800 |

100 |

6-8 |

| YG81--30 single cylinder |

7.5 |

1000*600*900 |

150 |

6-8 |

| YG81--40 single cylinder |

11 |

1000*600*900 |

200 |

6-8 |

| YG81--60 Twin cylinder |

15 |

1000*600*900 |

300 |

8-10 |

| YG81--80 Twin cylinder |

18.5 |

1200*800*1000 |

400 |

8-10 |

| YG81--100 Twin cylinder |

22 |

1200*800*1000 |

500 |

8-10 |

| YG81--120 Twin cylinder |

22 |

1200*800*1000 |

600 |

8-10 |

| Note: The above parameters are subject to technical changes, and the bale weight and productivity depend on the raw materials. |

.png) (1) The packing pressure ranges from 10 tons to 400 tons, with a full range of specifications. It can also be customized according to customer specifications.

(1) The packing pressure ranges from 10 tons to 400 tons, with a full range of specifications. It can also be customized according to customer specifications.

(2) This series uses an upper-mounted cylinder, which does not require an underground foundation, is easy to install, easy to maintain, and has high production efficiency.

(3) All cylinders use imported material seals, which are reliable and of good quality.

.png)

1. String the packing rope through the automatic elastic tightening device behind the baler, and place it along the packing belt groove, then bundle the packing belt to the pull station at the bottom end of the packing groove, rotate the automatic elastic tightening device 90 degrees, close the bottom door and lock it.

2. Put in the material, when the material is loaded to the height of the pressure plate, close the door tightly, and press the "down" button. The equipment runs automatically and compacts. (The feeding height of materials other than cardboard can only be slightly higher than the bottom door).

3. The pressure plate moves downward and returns automatically after the compression reaches the maximum pressure, returning to the fully open position. When compressing a pack constraint, the pressure plate stops at the preset position of the compressed material.

4. Open the door of the equipment, pass the rope from front to back through the bottom trunking and return to the front through the pressure plate trunking, and tighten the rope and tie the knot with your hands. Push the tie rod by hand, push the tie rod to a fixed position, and clamp it tightly. Press the "Up" button, and the return stroke of the cylinder will automatically turn out the bundled bales. (No one is allowed to stand in front of the door when opening the lower door, so as not to injure the door by popping open)

5. After the bundle is ejected, reset the packing lever for downward pressing. Finally, remove the bales, close the door and lock it to move on to the next packing cycle.

.png)

.png)

.png) (1) The packing pressure ranges from 10 tons to 400 tons, with a full range of specifications. It can also be customized according to customer specifications.

(1) The packing pressure ranges from 10 tons to 400 tons, with a full range of specifications. It can also be customized according to customer specifications..png)