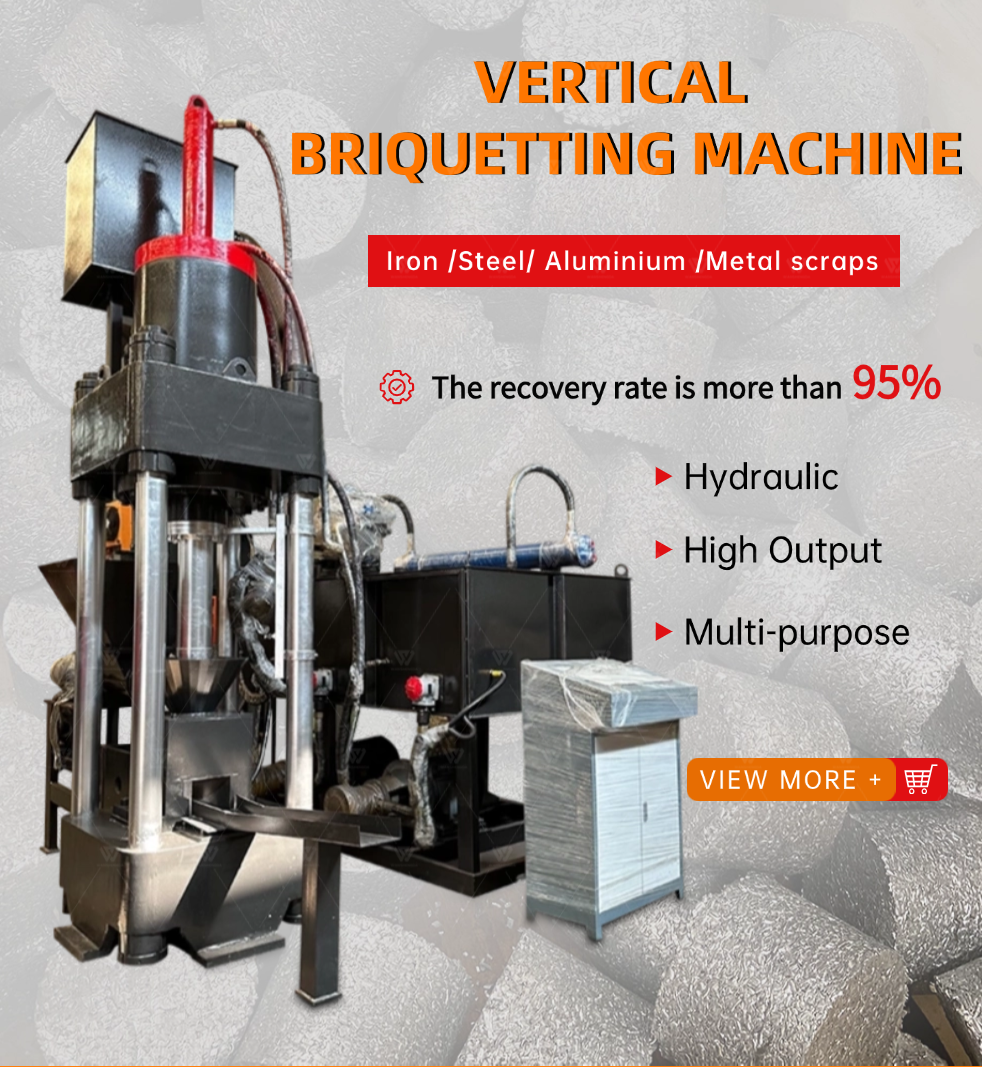

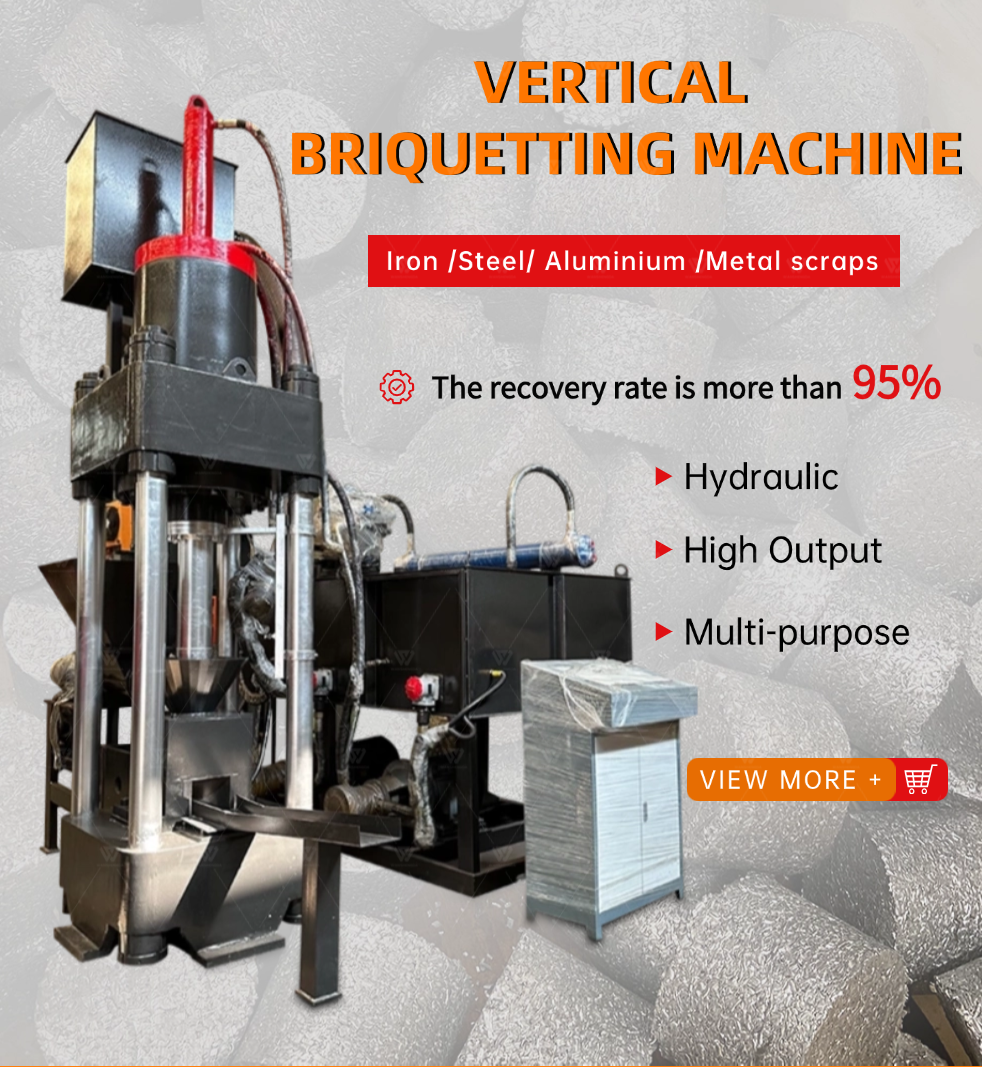

Vertical metal chip briquetting machine is suitable for putting cast iron chips, copper chips, aluminum chips, steel chips, alloy chips, magnesium chips (≤50mm), crushed materials (50~80mm), sawdust, grinder ash, wood chips, bamboo chips, paper scraps, iron ore powder, coke, nickel powder, sponge iron, silicon powder, slag powder and other waste materials through special molds, so that they can withstand high pressure on a very small area to be pressed into briquettes, which greatly facilitates the transportation of metal chips and reduces oxidation and burning loss during the smelting process to achieve significant economic benefits. It is an ideal equipment for use in metal smelters.

.png)

.png)

| Model |

WS-L160 |

WS-L200 |

WS-L250 |

WS-L315 |

WS-L400 |

WS-L500 |

WS-L630 |

WS-L800 |

WS-L1000 |

WS-L1250 |

| Nominal force (KN) |

1600 |

2000 |

2500 |

3150 |

4000 |

5000 |

6300 |

8000 |

10000 |

12500 |

| Block size (MM) |

Φ100-120x(60-80) |

Φ100-120x(60-80) |

Φ120-140x(80-100) |

Φ120-140x(80-100) |

Φ140-160x100-140) |

Φ160-180x(120-160) |

Φ180-200x(140-180) |

Φ200-240x(160-200) |

Φ220-260x(180-220) |

240-300x(200-260) |

| Block density (KG/M3) |

≥5000 |

≥5000 |

≥5000 |

≥5200 |

≥5200 |

≥5200 |

≥5200 |

≥5500 |

≥5500 |

≥5500 |

| Working pressure (MPa) |

20-25 |

20-25 |

20-25 |

20-25 |

20-25 |

20-25 |

20-25 |

20-25 |

20-25 |

20-25 |

| Productivity (T/H) |

0.25-0.4 |

0.4-0.6 |

0.6-0.8 |

1-1.2 |

1.2-1.5 |

1.5-2 |

2-3 |

4-6 |

6-80 |

10-12 |

| Total power (KW) |

18.5 |

18.5 |

22 |

30 |

37 |

22x2 |

30x2 |

45x3 |

55x3 |

75x3 |

| Equipment operation mode |

PLC fully Automatic |

PLC fully Automatic |

PLC fully Automatic |

PLC fully Automatic |

PLC fully Automatic |

PLC fully Automatic |

PLC fully Automatic |

PLC fully Automatic |

PLC fully Automatic |

PLC fully Automatic |

| Note: The above output and density are based on iron chips. The parameters are subject to technical changes. The productivity depends on the raw materials and the diameter and height of the briquette. |

.png)

1. Hydraulic drive, stable operation, no vibration, safe and reliable.

2. PLC control is adopted, and users can choose manual or automatic operation.

Note: The wear-resistant and consumable parts of the equipment (punch, inner grinding sleeve) must be replaced when the wear is too large, otherwise the equipment will be damaged.

.png)

.png)

.png)

.png)

.png)