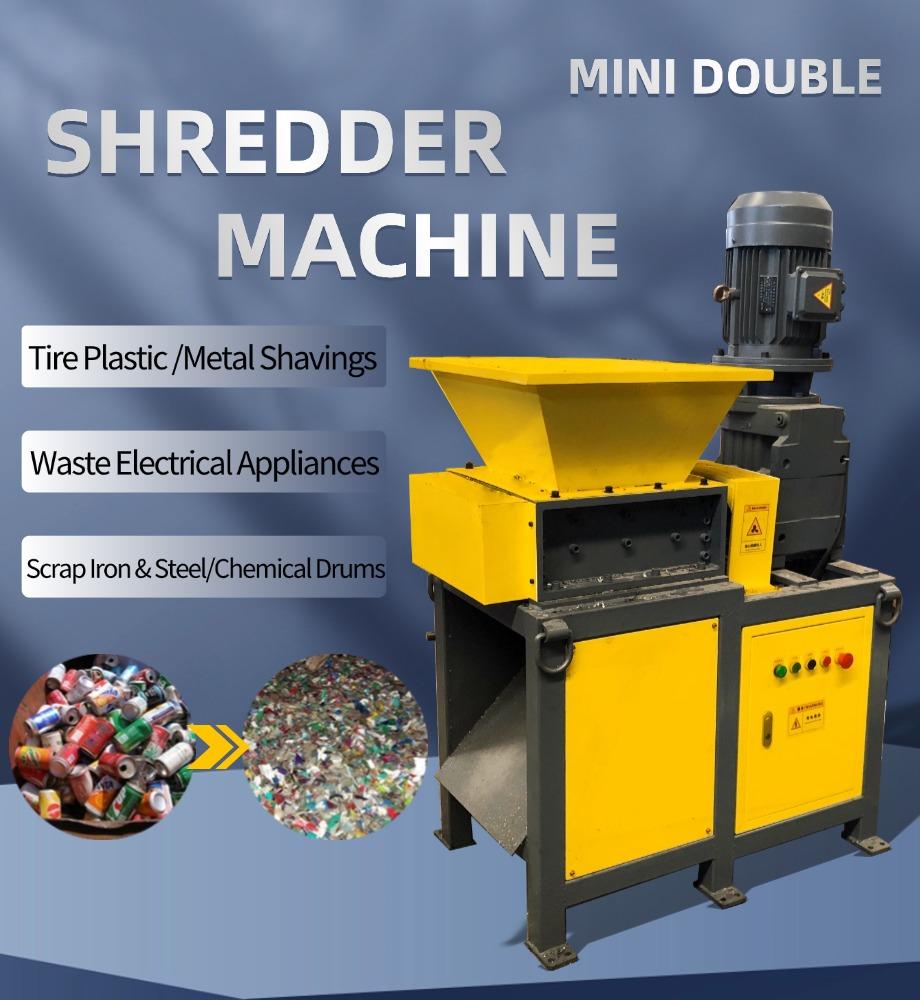

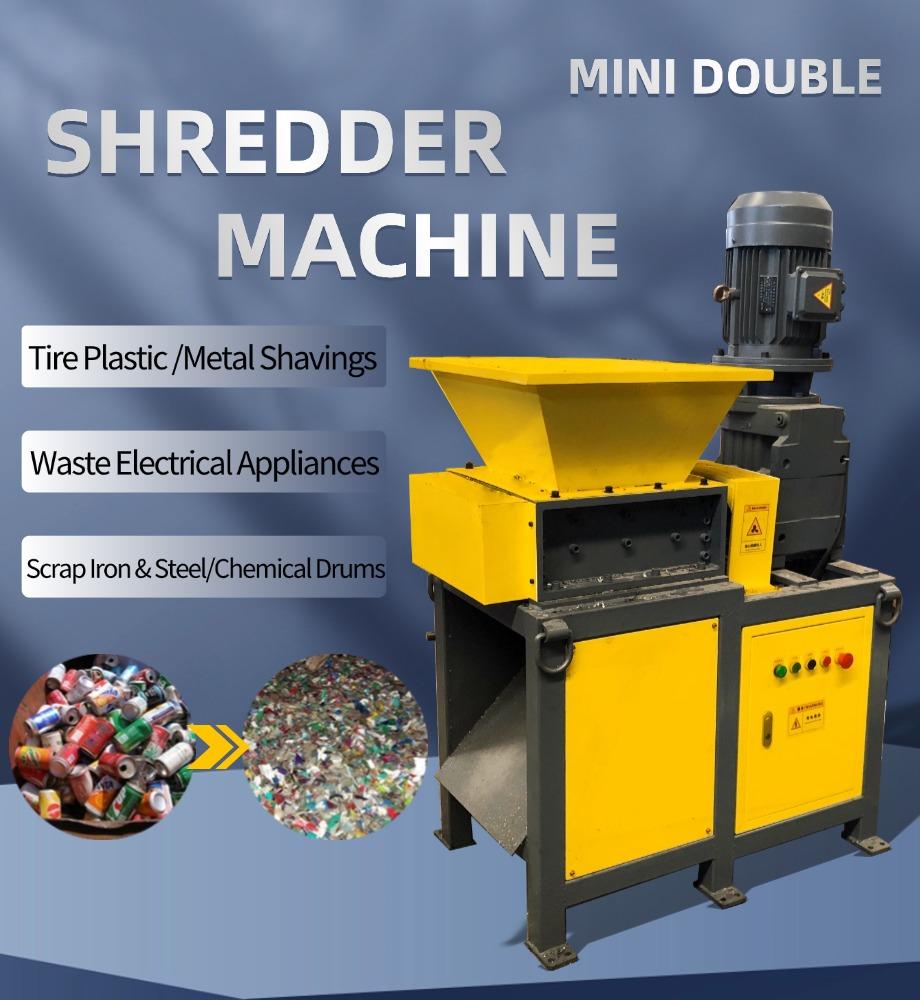

The main body of the shredder machine is produced in the whole one, using high-quality steel plate welding to eliminate the stress and to ensure the stability of the equipment in the long heavy load. The blade holder and blade on the rotor can be disassembled for easy cleaning, maintenance and maintenance; The plastic shredder machine has the advantages of even unloading, high tearing efficiency, large output, reliable performance, etc. It can be widely used in the garbage recycling industry.

Multi-functional waste shredder is widely used in industrial scrap metal recycling, plastic recycling, tire recycling, electronics manufacturing, pallet manufacturing, wood processing, paper industry, domestic waste recycling and other fields. It is suitable for crushing solid materials; For example electronic waste, metal, wood, plastic, waste tires, chemical drums, pallets and so on.

| Model |

Motor |

Speed(r/min) |

Tool Specifications |

Feeding port size (m) |

| WS-D150 |

3 KW |

13~20 |

160*10 |

0.8*0.4*0.7 |

| WS-D200 |

3 KW |

13~20 |

160*10 |

0.8*0.4*0.7 |

| WS-D300 |

4 KW |

13~20 |

180*10 |

1.2*0.45*1.2 |

| WS-D400 |

5.5KW |

18~25 |

180*10 |

1.3*0.5*1.25 |

| WS-D500 |

7.5KW |

18~25 |

200*20 |

1.9*1.3*1.5 |

| WS-D600 |

15KW |

18~25 |

200*20 |

1.45*0.87*2.2 |

| WS-D800 |

30KW |

18~25 |

300*20 |

2.2*0.87*2.15 |

| WS-D1000 |

30KW |

18~25 |

300*25 |

3.4*1.25*2.2 |

| WS-D1200 |

55KW |

18~25 |

400*40 |

4.15*1.25*2.2 |

| WS-D1500 |

75KW |

18~30 |

400*50 |

4.15*1.25*2.2 |

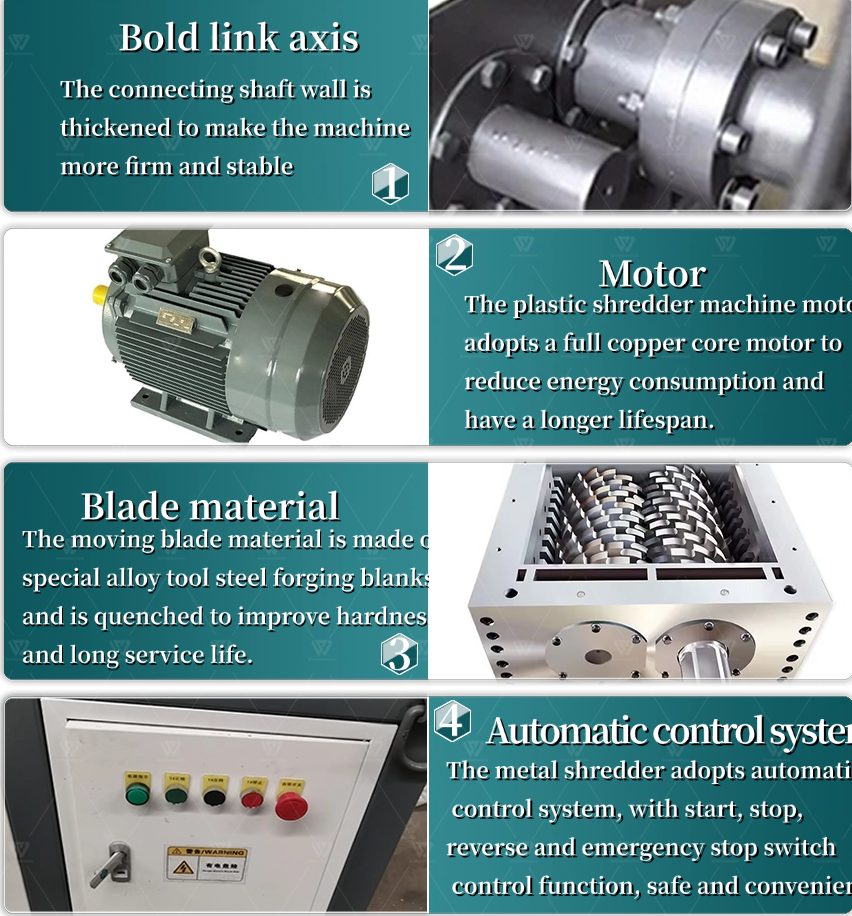

The knives of the waste paper shredder are made of special alloy steel by special processing, with better wear resistance, higher strength, repairable and other characteristics. The housing is flattened and disassembled, can quickly remove the movable knife, fixed knife, bearing, and other components, easy to maintain and replace tools.

.png)

.png)

.png)

.png)